Wheel hubs can be divided into two categories according to their materials: steel wheels and alloy wheels. The main advantages of steel hubs are simple manufacturing process, relatively low cost and strong resistance to metal fatigue. But the disadvantages are also obvious, such as heavy weight, large inertial resistance, poor heat dissipation and so on. The advantages of alloy wheels are light weight, high manufacturing precision, high strength, low inertial resistance, strong heat dissipation capacity, good visual effects, etc. The disadvantage is that the manufacturing process is complicated and the cost is high. JWHEEL can supply all kinds of wheels in the market.

Wheel classification

Wheel hubs can be divided into two categories according to their materials: steel wheels and alloy wheels.

1. The main advantages of steel hubs are simple manufacturing process, relatively low cost and strong resistance to metal fatigue. But the disadvantages are also obvious, such as heavy weight, large inertial resistance, poor heat dissipation and so on.

2. The advantages of alloy wheels are light weight, high manufacturing precision, high strength, low inertial resistance, strong heat dissipation capacity, good visual effects, etc. The disadvantage is that the manufacturing process is complicated and the cost is high.

Features of aluminum alloy wheels

The aluminum wheel hub is the product of "lightweight", "high speed" and "modernization", because it has many characteristics that are unmatched by steel wheels:

Light weight and obvious energy-saving effect: It is well known that reducing the weight of the vehicle can save fuel, and the wheels located in the driving part with the lowest center of gravity of the vehicle are even more important to reflect the energy-saving effect of the vehicle.

1) Different models and driving conditions have different fuel-saving effects.

2) The fact that the same vehicle can achieve obvious energy-saving effect by replacing steel rims with aluminum wheels is unquestionable.

Fast heat dissipation, high vehicle safety

The characteristics of high thermal conductivity of aluminum alloy wheels are extremely beneficial to the heat dissipation effect of the car tires due to high-speed driving, so that they are better than steel under the same conditions. It reduces the possibility of hot tires during long-distance high-speed driving, and significantly improves the safety performance of high-speed driving. It is easier to realize the "tubeless" of modern wheels. For a tubeless wheel, the original rubber inner tube is directly replaced by an aluminum rim. If a "puncture object" such as a nail is inserted into the outer wheel while driving, as long as it is not pulled out, it will not be removed. There will be an accident that the car rolls over due to a sudden flat tire like a tire with a tube. After a tubeless wheel encounters a "puncture object", it can generally last for at least an hour or even longer, which is particularly important for the safety of cars driving on the highway.

High dimensional accuracy and good vehicle driving performance

Cast aluminum wheels ultimately need to be processed by CNC machine tools, so no matter the roundness, end direction and radial accuracy of the wheels, they are not comparable to traditional rolled steel rings. The dimensional accuracy of the wheels directly affects the driving performance of the vehicle. Especially for high-speed vehicles, it is more prominent, such as the grip, yaw and stability of the whole vehicle during driving, and braking in case of an accident. The high speed and smooth driving of the car.

Changeable fashion styles are more suitable for the requirements of modern vehicles

1). The style is easy to change arbitrarily: using casting to make aluminum wheels, any spatial surface and shape can be made to match different models and meet the requirements of different users. The status of "green leaves lined with safflower" is becoming more and more prominent, and aluminum wheels have become the echo products of modern automobile fashion.

2). It is not easy to hide dirt and dirt, does not produce rust, is easy to clean, and is widely loved by drivers.

To sum up, it can be concluded that aluminum wheels are the product of "high-speed", "energy-saving" and "modern fashion" of automobiles. With the rapid development and development of the automobile market, aluminum wheels are used to gradually replace the traditional steel ring. The trend has become more and more intense, and there is an infinitely broad market prospect.

Wheel modification technology

Tires and wheels are inseparable

Many people usually choose a wheel that is larger than the original product when buying a new wheel. The first thing to pay attention to is that the tire and the wheel are two inseparable parts. During the modification process, try to keep the extension diameter of the tire. It is necessary to remain unchanged or to keep the changes as small as possible. One of the main reasons is that if the deviation is too large, the accuracy of the meter will be problematic. It's not feasible to just increase the wheel size without changing the tires. For example, if the tire size of the original car is 215/60R16 (16 means 16-inch wheels), then if you change to 17-inch wheels, the new tire size should preferably be 225/55R17, or 225/50R17.

There are three factors to consider when choosing a wheel:

One is size: don't blindly increase the hub. Some people increase the wheel hub to improve the performance of the car. Under the condition that the outer diameter of the tire remains unchanged, the large wheel hub is bound to match the wide and flat tire. The lateral swing of the car is small, and the stability is improved. pass by. However, the flatter the tire, the thinner the thickness, the worse the shock absorption performance, and the greater the sacrifice in terms of comfort. In addition, the tires are easily damaged if there are some roadblocks such as stones. Therefore, the cost of blindly increasing the hub cannot be ignored. Generally speaking, it is most appropriate to increase one or two sizes according to the size of the original wheel hub.

Second, the hole distance, screw eye distance and eccentric distance must be suitable for the model. This means that when choosing, you can't choose the shape you like at will, and you must follow the advice of the technician to consider whether the three distances are suitable.

The third is the shape: the complex and dense wheel hub is indeed beautiful and classy, but it is easy to be refused or overcharged when washing the car, because it is too troublesome to wash. The simple wheels are dynamic and clean.

Wheel modification technology

1. Schematic diagram of tire and hub coordination

As shown in the picture, the degrees A and C are unreasonable wheel and tire fit, and can even be said to be very dangerous. The best fit is shown in Figure B. The inner sidewall of the tire is within the two extension lines of the wheel lip of the hub. Only in this case is the combination of tires and wheels the most reasonable, and only in this case can the best performance of tires and wheels be exerted.

2. Schematic diagram of wheel hub installation:

(1) Make sure that the hub is placed on the same level of the screw;

(2) The bolts (females) must be clean. If the bolts (females) are loose, they need to be tightened or replaced;

(3) Remember: Follow the correct way of tightening the hub.

Frequently used parts for wheel upgrades

shaft collar

The center hole of the OEM rim is specially produced for the model, and the center hole collar is not used.

The size of the center hole of AFTERMARKET's rim varies from manufacturer to manufacturer, with the largest being 73.1mm.

There are hundreds of specifications of the hole ring.

PCD Gasket (Wasser)

Because the aluminum alloy material is soft, some wheel hubs (such as off-road vehicles or pickups) that require large torque will be fixed in the bolt holes of the wheel hub by extrusion. play a protective and protective role. Some wheel hubs require a strong air gun and also require a washer. WASHER is mostly made of zinc alloy.

Gas nozzle

TR413, TR413C are the most commonly used, and there are also color covers with aluminum alloys for good look

Gas nozzle

TR413, TR413C are the most commonly used, and there are also color covers with aluminum alloys for good looks.

Precautions:

After each wheel hub change, be sure to check the wheel hub again when the vehicle travels about 30Km, and re-tighten the loose bolts. The most important thing when installing the wheel hub is to follow the specified torque. If it is too loose, long-term driving will cause the wheel hub to become loose or even fall off. If it is too tight, it will cause the wheel hub bolt to crack or even break, which is extremely dangerous in actual use.

Positioner (ADAPTER)

If you really like a certain wheel hub, but the PCD is wrong (for example, the car is 4 holes X100, and the wheel hub is 5 holes X114.3), you can use the displacer (ADAPTER). Sometimes the displacer is also used to widen the wheel base special needs. The positioner is forged by aluminum alloy, and the thickness is generally not less than 19MM.

Bolt Nut

The hub bolts used in cars are generally M12 and M14. The German series mostly use M14, and Japan uses M12. German cars mostly use bolts, and Japanese cars mostly use nuts.

Due to the need for lightweight, light alloy wheel nuts are popular in Japan. Usually aluminum alloys, but also titanium alloys and others. The colors are more bright to meet individual needs.

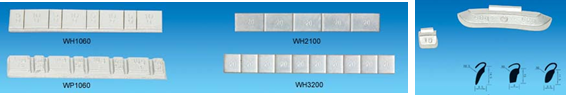

Depending on the shape of the hub, use a clip-type or stick-type balance weight. Most of the wheels have the balance weight on the inside of the wheel, so it is difficult to find the balance weight from the outsi