Hubert Mies, who has extensive experience in designing cars for Ford and Tesla, explains why the mainstream of wheels has changed from "disc wheels" with deep indentations to "flat wheels" with shallow indentations and flat surfaces. Flat wheels" with shallow dents and flat surfaces.

What is the reason for the widespread adoption of 'flat wheels' in cars today?

Hubert Mies, who has extensive experience in designing cars for Ford and Tesla, explains why the mainstream of wheels has changed from "disc wheels" with deep indentations to "flat wheels" with shallow indentations and flat surfaces. Flat wheels" with shallow dents and flat surfaces.

This is why car wheels are now so flat (no, it's not just aerodynamics and styling)

While cars released a few decades ago often used disc wheels with deep dents on the left side, many cars that have appeared in recent years have flat wheels like those on the right. Changes in wheel shape are also greatly influenced by changes in design trends, but Mr Mies points out that "changes in the mechanism of steering" also affect the shape of the wheel.

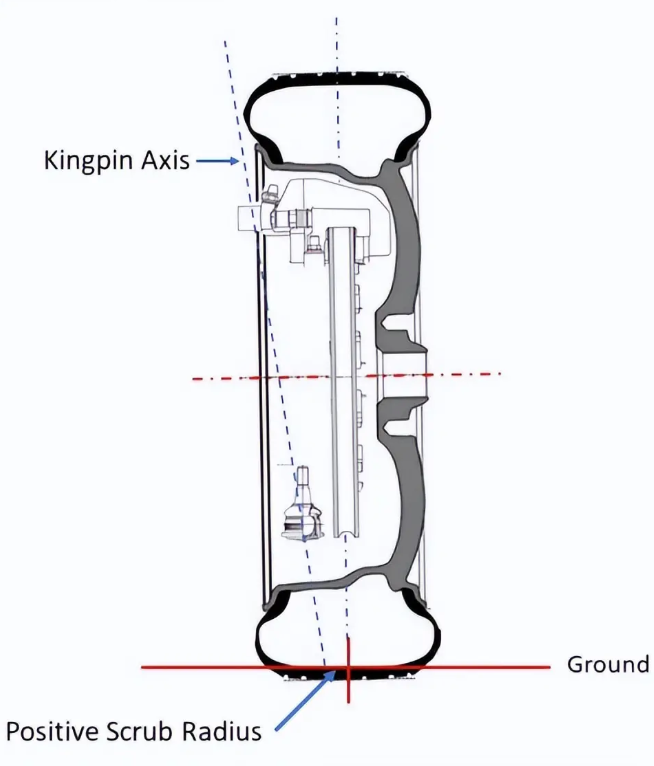

When the steering wheel is operated, the tyres do not rotate around the centre of the ground because the axis of rotation of the wheel steering is not at the centre of the wheel, but around a part slightly off the centre of the ground.

This distance from the intersection of the extension of the steering axis with the ground to the tyre's ground centre is known as the "scurb radius". According to Mr Mies, the greater the scurb radius, the greater the force repelling the steering wheel operation (the force of trying to return to a straight line), so it is best to keep the scurb radius as small as possible. If you try to reduce the wear radius, you need to move components such as the car's brakes to the outside of the tyre without leaving any room to recess the wheel. This is why modern cars use flat wheels.

As mentioned above, reducing the wear radius reduces the "linear return force". However, the 'ball and nut steering' that was the norm in commercial vehicles decades ago has less 'straight-line return force' than the 'rack and pinion steering' that has become the norm in recent years, allowing the driver to turn. One problem is that it is not as sensitive and precise. The advantage is that in cars with 'ball and nut steering' there is no need to reduce the wear radius and there is a space inside the tyre just large enough to fit the recessed hub.

The change in wheel shape when the steering mechanism is changed from 'ball and nut steering' to 'rack and pinion steering' looks like this. Firstly, a photo of a 2000 Ford Expedition showing the deeply dented 'disc wheel'.

Then, the 2004 Ford Expedition uses "rack and pinion steering" flat wheels.

According to Mr Mies, the change in wheel shape was also influenced by the need to optimise aerodynamic characteristics. At the end of his comments, Mies revealed that he liked the look of the deeply dented disc wheels, saying, "I hope that disc wheels will continue to be used on cars."

The flattened tyres also drive the new wheel style, creating a different car stance.

Jwheel, as an professional wheel manufacturer, concentrates in R&D and manufacturing of aluminum alloy wheels, including casting wheels, forging wheels and flow-form wheels. The products of it have passed the certifications of SEI、SEMA,VIA, JWL, JWL-T, TUV and so on. Since establishment, Jwheel has been developing steadily, with rich experience of designing and producing aluminum alloy wheels. It has earned the appreciation of both domestic market and foreign market with its high technology, good quality and customer service. It provided OEM service to many international brands like Vossen, OE Wheel, TSW, Rays, ProLine, Oxygen, AUTEC, etc., and it also provide ODM service, that is, for producing a new wheel, you can just provide a sketch, drawing or picture, and then Jwheel will finish the rest parts. By the way, the MOQ of forging wheels is four. (For more information, just go to the website: https://www.jjjwheel.com)

J126 18x8 42 120x5 67 AAP/U35AR 690KG