The wheel has been involved in the evolutionary progress of society since the ancient days of the rickshaw to the horse-drawn carriage. The material of the wheel has also evolved from wood to steel (iron) to alloy, and the production process from casting to spinning to forging.

Let's start with the structure of the wheel and some common parameters:

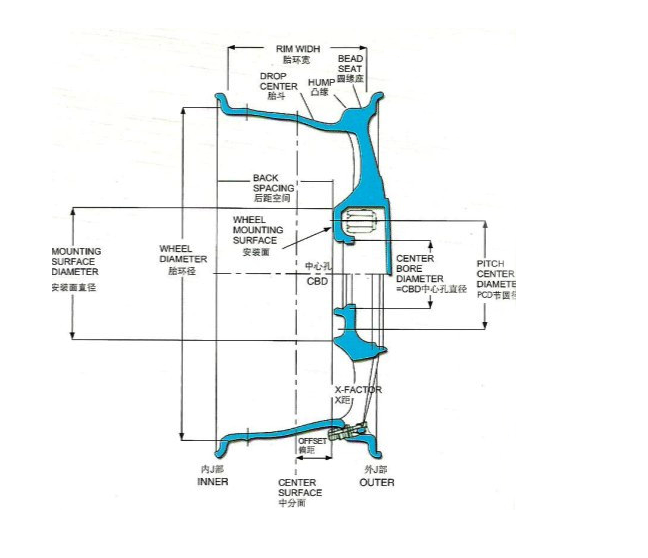

Detailed labelling of the wheel:

The wheel has been involved in the evolutionary progress of society since the ancient days of the rickshaw to the horse-drawn carriage. The material of the wheel has also evolved from wood to steel (iron) to alloy, and the production process from casting to spinning to forging.

Let's start with the structure of the wheel and some common parameters:

Detailed labelling of the wheel:

The parameters that we most often encounter when shopping for wheels are

Offset (ET value)

Common definition: The offset is the distance from the face of the wheel used to attach the screws (fastening surface) to the centre line of the wheel.

1. Positive offset

Positive offset means that the fastening surface is to the outside.

Positive pitch wheels are commonly used for front-wheel drive and some rear-wheel drive models, such as cars and passenger cars.

Negative Pitch

Negative pitch means that the fastening surface is further in than the hub centreline (i.e. the brake disc).

inwards (i.e. brake discs)

Negative pitch wheels are commonly used in SUVs, premium cars and sports cars.

Note: Incorrectly spaced wheels can lead to tyre pick-up, tyre wall wear, obstruct steering and have a serious impact on safety.

This can have a serious impact on safety.

Supplementary: What if we really like a wheel but it does not have the appropriate offset value?

We can solve this by using offset spacers or flanges. When using either of these tools to adjust the offset, it is best to use stronger fixing bolts, otherwise there is a risk of the bolts being overloaded and breaking.

Bolt hole spacing:

The professional name for wheel hole pitch is pitch circle diameter, which refers to the diameter between the fixing bolts in the centre of the wheel. Generally, most of the wheel holes are 5 bolts and 4 bolts, but the distance between the bolts varies, so we can often hear such names as 4X103, 5X114.3, 5X112, taking 5X114.3 as an example, it means that the PCD of this wheel is 114.3mm. The holes are for 5 bolts.

Further information

It is often said that the width of the wheel is 7J, 8J, the number here represents the width of the wheel, while J only represents the shape and height of the wheel flange. In addition to J we have C, JJ, JK, K, etc., which are mainly different for the height of the projection respectively, C being the lowest and K the highest, while J is the most common type of wheel. For example, 7J means that the distance between the flanges on both sides of the wheel is 7 inches.

The two pictures below are details of the meaning and conversion of J values.

The earliest automotive wheels

The earliest car wheels were inherited from horse-drawn carriage wheels consisting of dense strips, the strips and the rim and hub were detachable from each other. Unlike today's alloy wheels include the entire section. The wheels of the carriage type were separable in three parts.

Then came the very familiar steel (iron) wheels, the earliest of which were completely naked and looked unattractive.

The first steel wheels were completely naked and looked unattractive. Later on, beauty lovers devised something called a "hubcap", usually made of plastic, to cover the outside of the rim. At first it was meant to hide the ugly, but later it turned out to be quite beautiful. Gradually they became a popular feature on some lower end models.

As technology progressed, various manufacturing processes emerged, such as spinning and forging, which made the wheels lighter, better looking and stronger.

Jwheel, as an professional wheel manufacturer, concentrates in R&D and manufacturing of aluminum alloy wheels, including casting wheels, forging wheels and flow-form wheels. The products of it have passed the certifications of SEI、SEMA,VIA, JWL, JWL-T, TUV and so on. Since establishment, Jwheel has been developing steadily, with rich experience of designing and producing aluminum alloy wheels. It has earned the appreciation of both domestic market and foreign market with its high technology, good quality and customer service. It provided OEM service to many international brands like Vossen, OE Wheel, TSW, Rays, ProLine, Oxygen, AUTEC, etc., and it also provide ODM service, that is, for producing a new wheel, you can just provide a sketch, drawing or picture, and then Jwheel will finish the rest parts. By the way, the MOQ of forging wheels is four. (For more information, just go to the website: https://www.jjjwheel.com)

J267 P2027 15x6 33/44 139.7*6H 100/106 C+F5/A/GM20/S42