Low-pressure casting in the other hand takes care of the disadvantages of Gravity casting by filling the mould through an in-gate just below the top of the mould cavity from a source under the mould through a method which allows complete filling of the mould. The force of gravity acts against the upward flow of the metal and eliminates the possible turbulence caused by the falling liquid metal. The molten metal is stored in a pressured container and by increasing the pressure metal is then forced into the mould.

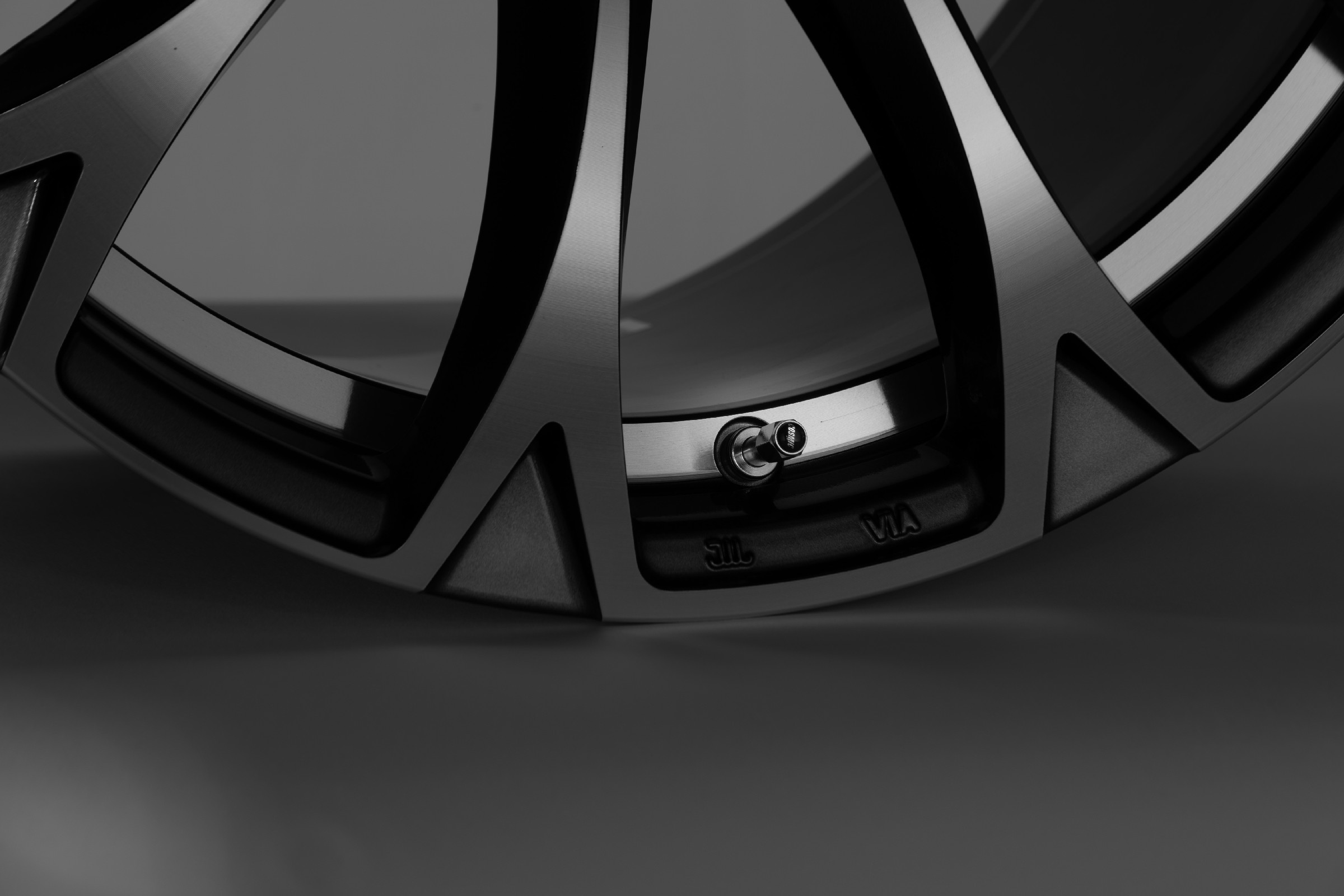

Applicable Models:Volkswagen, Audi, Mercedes-Benz, Honda, Toyota, Hyundai, Kia, Mazda, Nissan

https://www.jjjwheel.com

Low-pressure casting in the other hand takes care of the disadvantages of Gravity casting by filling the mould through an in-gate just below the top of the mould cavity from a source under the mould through a method which allows complete filling of the mould. The force of gravity acts against the upward flow of the metal and eliminates the possible turbulence caused by the falling liquid metal. The molten metal is stored in a pressured container and by increasing the pressure metal is then forced into the mould.

The advantages of low pressure die casting process are several :

- higher yield achievable

- reduction of machining costs

- excellent control of process parameters

- good metallurgical quality

- leads to an optimal use of the aluminum

- excellent mechanical and technological properties of the castings.

Contact Us

Leave A Message

Recommended