FAQ

1.Q: Can you accept my own logo on the product or Customize my idea?

A: Yes.

2.Q: How long can I get feedback?

A: Within 24 hours once received your inquiry.

3.Q: Where’s your factory ?

A: My company is in Jiangmen City, just need 1 hour from GuangZhou BaiyunStation to our factory.

Advantages

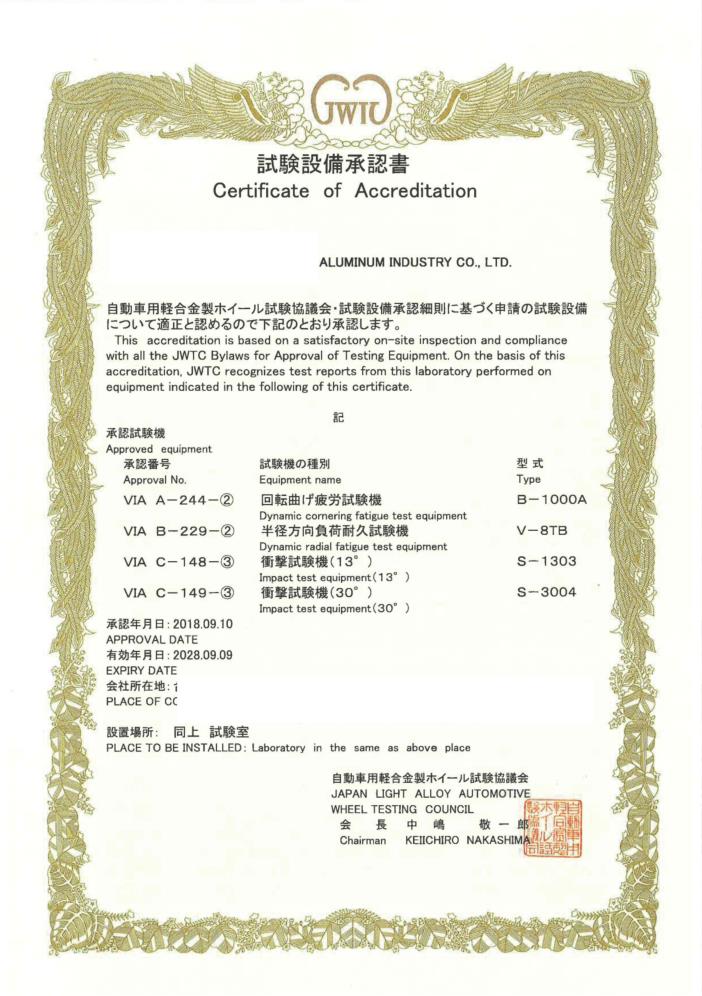

1.The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

2.The company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

3.We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

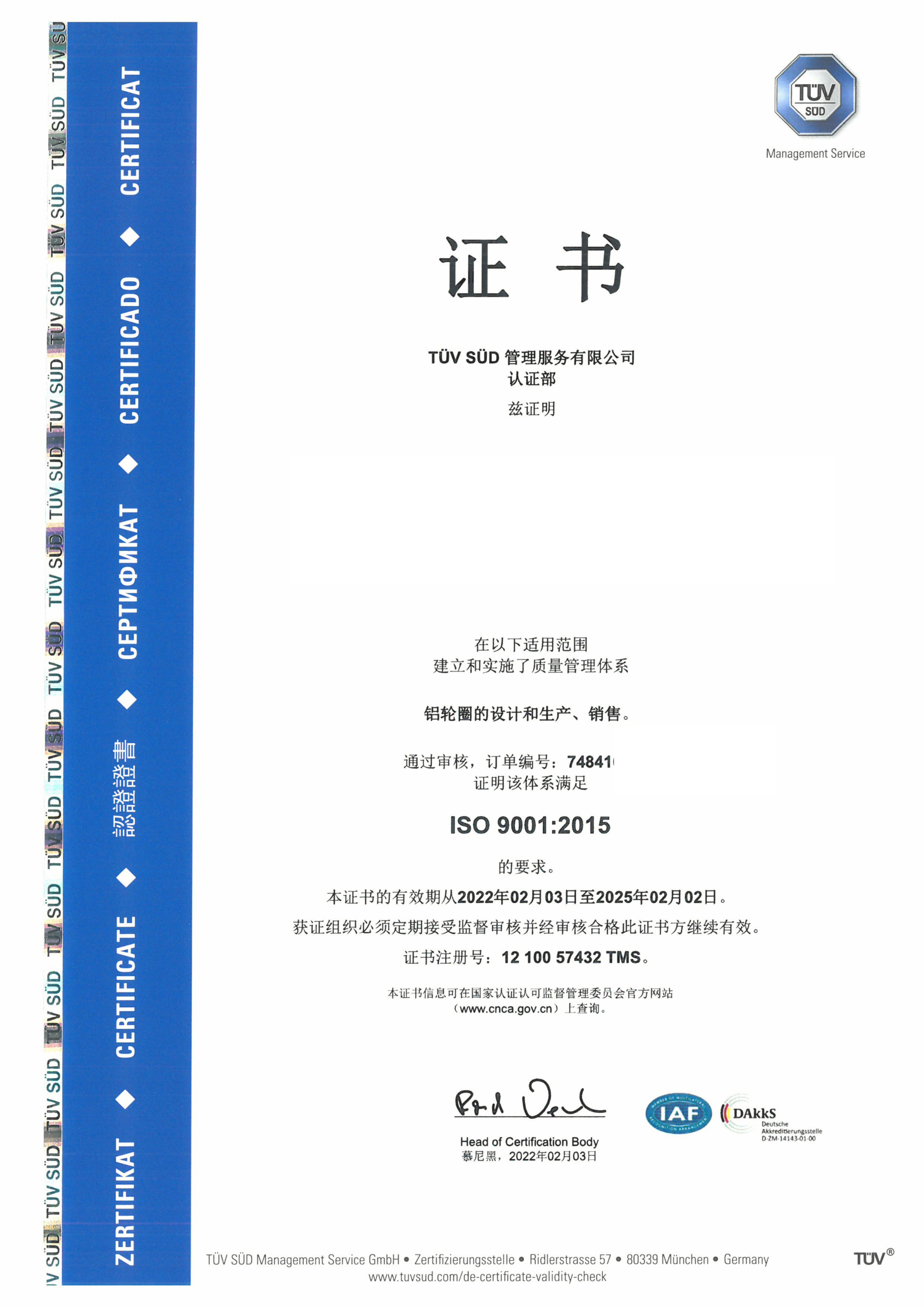

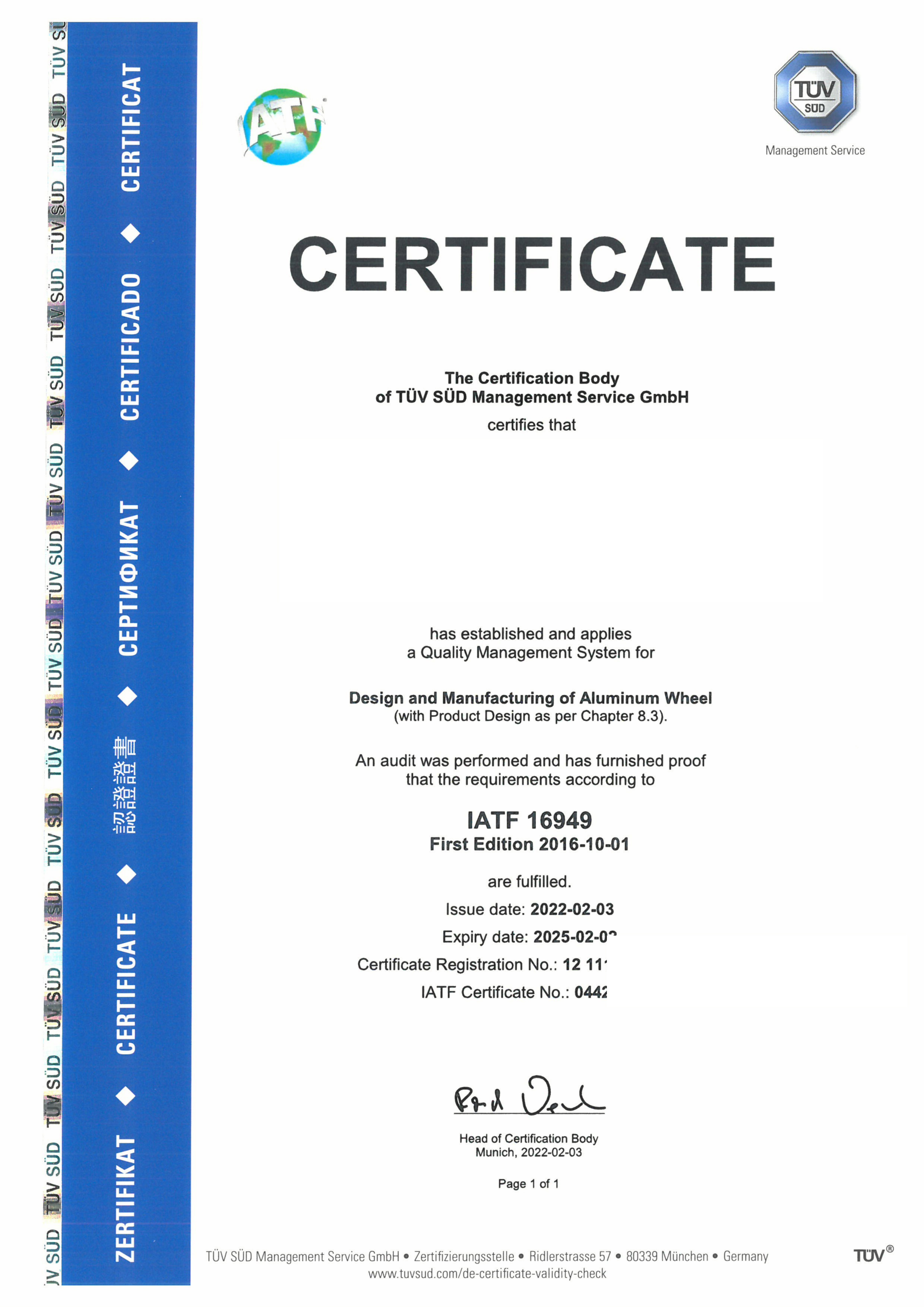

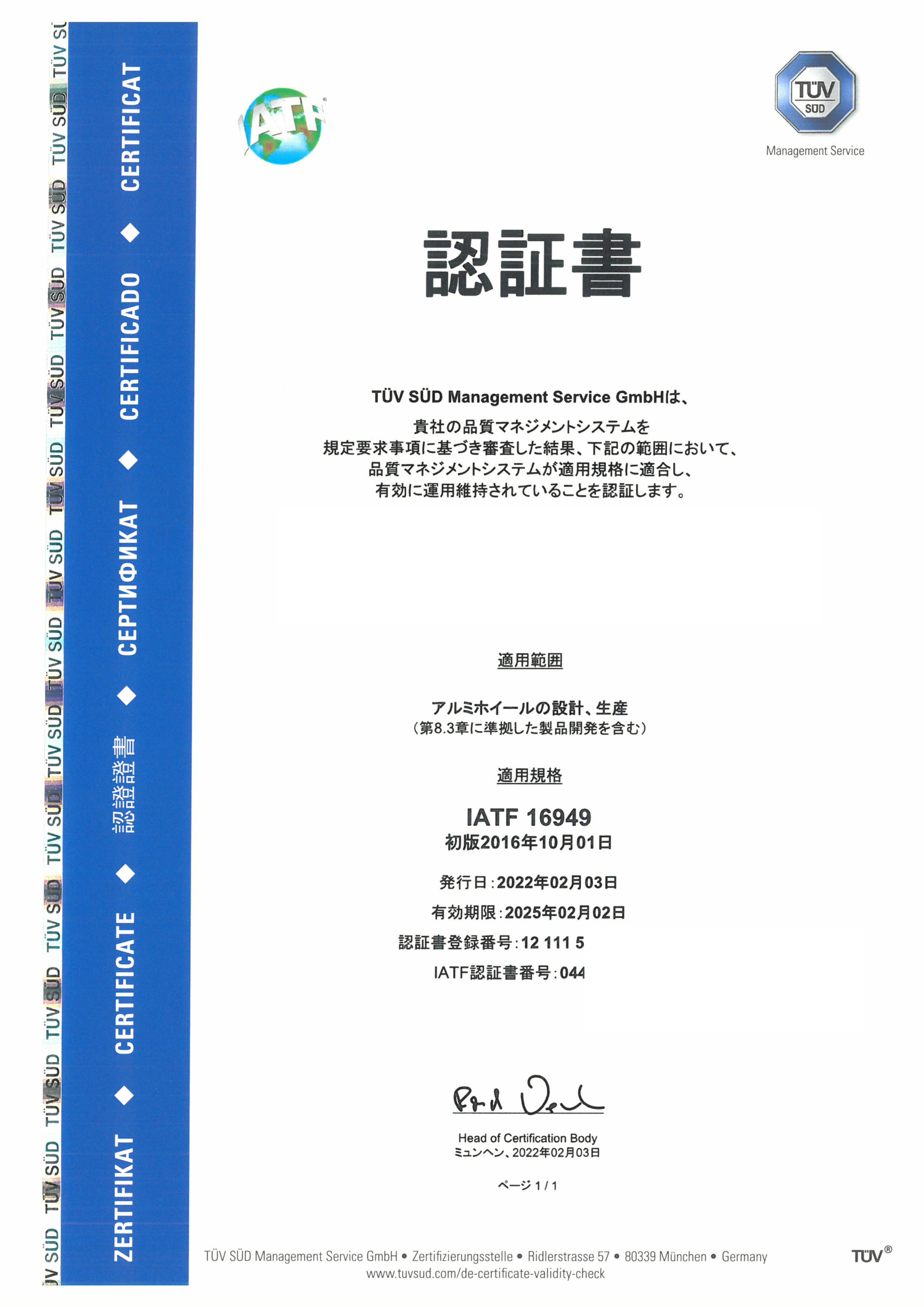

4.The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification).

About JWHEEL

GuangChuan has its first plant established in 1993. After over 29 years’ development, GuangChuan has become a world-leading supplier for many international famous wheel brands. GuangChuan has an annual production capacity of 1.5 million and it provides one-stop solution for design and manufacturing. It’s equipped with advanced production facilities such as aluminum alloy melting furnace, casting production line, spinning and forging equipment, automatic painting line, helium leak detection system and automatic dynamic balance inspection system.

Product Introduction

Certifications and Patents