The knowlege of the production method of wheels is very important for choosing a wheel.

In the last passage we introduced the structure and classification of wheels. A wheel consist of the following parts:

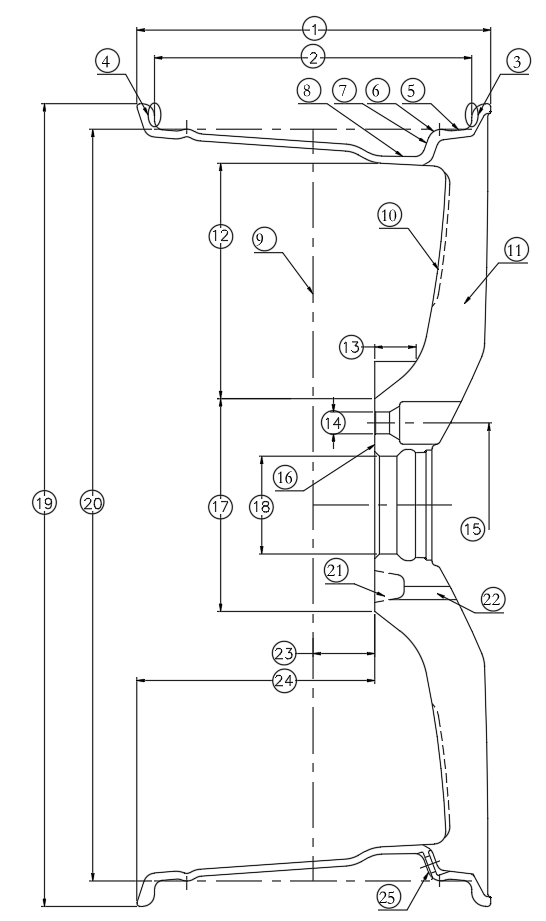

1 Total Width

2 Rim Width (Tire Width)

3 Front Lip

4 Back Lip

5 Bead Seat

6 Hump

7 Inclination

8 Drop Center

9 Center Line

10 Rib Weight Reduction Pocketing

11 Rib ( Spoke)

12 Y Factor

13 X Factor

14 Bolt Hole Diameter

15 Pitch Center Dia(PCD)

16 Mounting Surface

17 Mounting Surface Dia

18 Central Bore (CB)

19 Outer Diameter

20 Wheel Diameter

21 Mounting Surface Weight Reduction Pocketing

22 Vent

23 Offset (ET)

24 Back Spacing

And there are types of wheels: Steel wheels, aluminum alloy casting wheels, aluminum alloy forged wheels, carbon fibre composite wheels, and magnesium wheels.

In this passage, we will mainly introduce the ways of manufacturing wheels.

There are mainly two ways to manufacture wheels: forging and casting.

Casting can be divided into gravity casting and low-pressure casting machine, it is to melt the aluminum ingot into liquid, which is then injected the liquid into a mold and cooled down. In this process, the aluminum is transformed from solidity to liquid, and injected into the mold, so air and some other stuff might go into it, which have a high requirement for the technology of the factory.

Forged wheels do not have this problem because it is to press the aluminum which is in common temperature or heated with the pressure of 8000 to 10000 tons, during which the form of the aluminum doesn’t change, meanwhile the high pressure makes wheels with higher density and solider structure.

Therefore, forged wheels are lighter and more solid than casting wheels, which means forged wheels save more fuel. However, nowadays many factories would produce wheels with low-pressure casting and flow form to make the quality of the wheels close to that of the forged wheels, so flow form casting wheels are a good choice with high quality and lower prices.

Usually the price of a gravity casting machine is 3 to 4 thousand USD, a low-pressure casting machine 15 to 30 thousand USD, and a forging machine 3 to 7 million USD. This brings a large difference to the prices of these three kinds of wheels. So when you try to get a set of wheels from eBay or Alibaba, you should pay attention to the manufacturing ways of the wheels. If you find a forged wheel that’s cheaper than others, you should be careful. And as the manufacturing is a costly process, some factories are not able to be equipped with good machines that meet the standards, the wheels they produce are in low quality. Therefore, it’s very important to find the wheels that are produced by certified and powerful plants which are equipped with advanced facilities and completed testing labs, which can effectively let you avoid getting the wheels with problems and wasting money. JWHEEL is one of them.

JWHEEL is a professional manufacturer with a history of 30 years, and have become the suppliers of many international wheel brands, providing both ODM and OEM services to them, so we have sufficient experience to produce a variety of wheels in good quality. And it has tremendous ability on aluminum alloy wheel design and provides one-stop services from design to production, equipped with aluminum alloy furnace, casting line, forging machine, flow forming facility, automatic painting line, helium leak detector, automatic balance check system, etc.. With these advanced technology, JWHEEL’ s production capacity now has exceeded 1.5 million wheels per year. ( For information about wheels, just go to the website: www.jjjwheel.com.)