There are actually many benefits to a safe and sensible modification of the wheels.

In addition to the visual comfort that comes with changing a set of wheels, the greater advantage is also reflected in the handling, in addition to giving up the original car's bulky and tacky wheels and replacing them with a set of wheels that you are happy with.

The most direct reaction to the lighter wheels is the reduced underspring mass, which results in a much lighter steering feel and clearer road feedback, which ultimately reflects in the handling of the vehicle.

As for the reduction in fuel consumption, I guess it varies from person to person. Because the level of fuel consumption is directly linked to the driver's driving style.

The 20 or so pounds you save by replacing the lightweight wheels is not really as much as you would get from two kicks of floor gas.

Save your money, save your life: "Internet celebrity" wheels in trouble, fancy and unsafe

A broken wheel can lead to a serious accident.

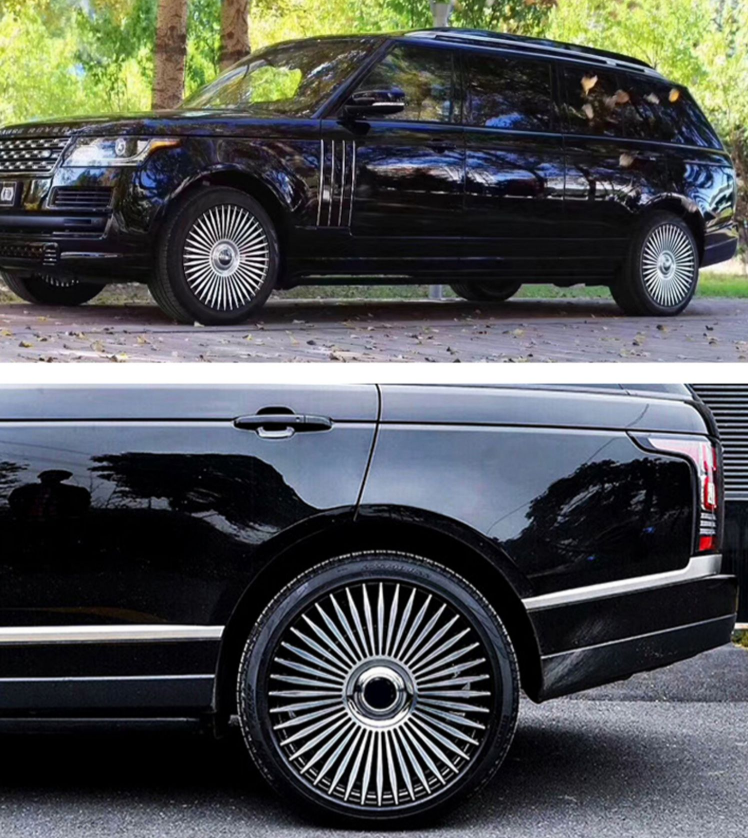

Even if you don't look at the car, just at the wheel, I know it's a Land Rover "suspension wheel"

I don't know why, but this is one of the most popular Land Rover wheels, and I see it on the street all the time.

It's not an exaggeration to say it's suspended, because when it turns, the logo in the middle doesn't move, a bit like the "big pancake hub" on a Mercedes.

The safety of these wheels is a concern.

The original wheels are heavy and ugly, especially on low-end cars with steel rims and a plastic shell, which is ugly as hell.

Despite the fact that the original wheels are ugly and heavy, they have been subjected to strict production standards and reliable durability tests.

The production method used by the average car manufacturer for mass-produced wheels is either low-pressure casting or gravity casting.

This production method is the most efficient and the cheapest, but the biggest disadvantage is the high weight and the plain shape.

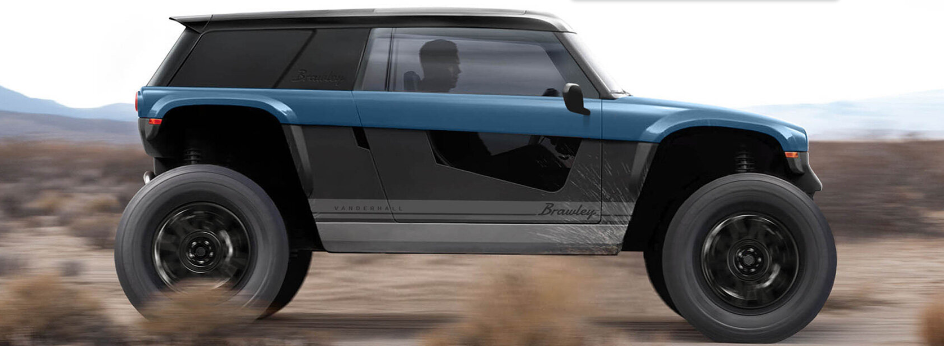

In the mind of a car enthusiast, a car needs a more distinctive set of "shoes". This is why the lighter and more sophisticated spun cast and forged wheels are so popular with this group.

However, the so-called forged and spun cast wheels are now a mixed bag in the market.

You can buy M-Power, AMG and RS mesh wheels at the same price as cast ones, but of course there are some big manufacturers, but many people still choose the horribly cheap ones.

Many of the net wheels are advertised as lightweight, but there is no way to measure the weight of a wheel with one shape and one weight.

Without the requirements of production standards, net wheels made for face value only, which claim to be harder, are prone to deformation and even breakage when crossing potholes at high speeds, leading to accidents.

Of course, there are actually many benefits to a safe and sensible modification of the wheels.

In addition to the visual comfort that comes with changing a set of wheels, the greater advantage is also reflected in the handling, in addition to giving up the original car's bulky and tacky wheels and replacing them with a set of wheels that you are happy with.

The most direct reaction to the lighter wheels is the reduced underspring mass, which results in a much lighter steering feel and clearer road feedback, which ultimately reflects in the handling of the vehicle.

As for the reduction in fuel consumption, I guess it varies from person to person. Because the level of fuel consumption is directly linked to the driver's driving style.

The 20 or so pounds you save by replacing the lightweight wheels is not really as much as you would get from two kicks of floor gas.

The only thing you can say is that the overall fuel consumption will be slightly reduced, so don't expect to save a few kilometres.

Finally, I would like to make a sincere appeal: for the sake of your driving safety, don't buy those wheels that cost a few hundred dollars anymore. The whole thing is fancy, and ultimately it's your own safety that is affected.

Jwheel, as an professional wheel manufacturer, concentrates in R&D and manufacturing of aluminum alloy wheels, including casting wheels, forging wheels and flow-form wheels. The products of it have passed the certifications of SEI、SEMA,VIA, JWL, JWL-T, TUV and so on. Since establishment, Jwheel has been developing steadily, with rich experience of designing and producing aluminum alloy wheels. It has earned the appreciation of both domestic market and foreign market with its high technology, good quality and customer service. It provided OEM service to many international brands like Vossen, OE Wheel, TSW, Rays, ProLine, Oxygen, AUTEC, etc., and it also provide ODM service, that is, for producing a new wheel, you can just provide a sketch, drawing or picture, and then Jwheel will finish the rest parts. By the way, the MOQ of forging wheels is four. (For more information, just go to the website: https://www.jjjwheel.com)

has been improved on the basis of the old types and such properties as have been realized.

FAQ

1.Q: How long can I get feedback?

A: Within 24 hours once received your inquiry.

2.Q: Where’s your factory ?

A: My company is in Jiangmen City, just need 1 hour from GuangZhou BaiyunStation to our factory.

3.Q: What’s your delivery time?

A: 35-60 days after deposit is done.

Advantages

1.The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification).

2.The company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

3.The company is located in Guangdong, Hong Kong and Macao Bay Area, an important node city of Jiangmen. With modern production facilities, we adopt the industry's advanced casting, machining, painting and inspection equipment, equipped with automatic robots throughout the process, and with ERP system and other advanced management means, to create the industry benchmark for hardware, software and product quality.

4.We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

About JWHEEL

Guangdong Guangchuan Auto Parts Trading has its first plant established in 1993. After over 29 years’ development, Guangchuan Auto Parts Trading has become a world-leading supplier for many international famous wheel brands. Guangchuan Auto Parts Trading has an annual production capacity of 1.5 million and it provides one-stop solution for design and manufacturing. It’s equipped with advanced production facilities such as aluminum alloy melting furnace, casting production line, spinning and forging equipment, automatic painting line, helium leak detection system and automatic dynamic balance inspection system.