As a car lover, when buying a car, the original wheels will be replaced. The reason for this is that with the original models, the design is not good enough to personalise.

As a car lover, when buying a car, the original wheels will be replaced. The reason for this is that with the original models, the design is not good enough to personalise.

Aluminium wheels come in a variety of designs and the basic design rule is to match the contours of the bodywork. Appearance is a top priority, but is the design related to driving performance?

There are differences in performance depending on materials such as aluminium and magnesium and manufacturing methods such as casting and forging, which also relate to stiffness, strength and weight. Also, castings allow a lot of design freedom but require a set of moulds for each style parameter, while forging processes can be limited, so here's the first link between performance and design.

In terms of design, the number and thickness of spokes has a significant impact on performance. If the spokes are larger or thicker, they will be more rigid and stronger, making it difficult to create a nice wheel style, but giving the impression of sturdiness. Conversely, with slim 6 or 8 spokes, the image will be light and sporty. However, if they are not designed well and are not strong enough, they can break, so be careful. Of course JWHEEL designs its models with mock-ups, then trial production, and after a series of tests, official production, so you can be absolutely sure of the quality.

It seems incredible that wheels can break, but it is not uncommon for spoke bases to break if driven on roads with poor road conditions. However, the lightness is an important point and will lead to a reduction in unsprung weight, which will help boost speed. It is fair to say that a proper aluminium wheel is not only about design, but also about weight, rigidity and strength.

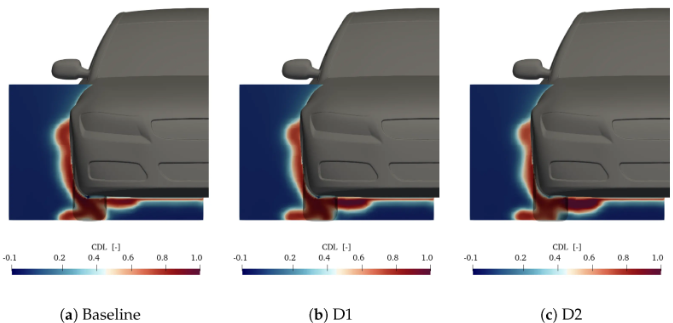

More recently, aerodynamics has been influencing wheel design. Wind tunnel testing and analysis are being used to radically reduce the aerodynamics around the bodywork, but the wheels and tyres have remained untouched until now and there is still room for improvement.

There is potential for an increase in the range of finned wheels in the future, but if we go for aerodynamic performance, the design style may become less than desirable, so it is difficult. Finding a balance between design and performance will always be a difficult task.

The design of JWHEEL is carried out considering many important factors that are related to human health. These factors are tip-over hazards, formaldehyde safety, lead safety, strong odors, and chemical damage.

FAQ

1.Q: What kinds of method do you use to put customized logo?

A: Silk screen printing. Laser engraving. Stamping.

2.Q: Can you accept my own logo on the product or Customize my idea?

A: Yes.

3.Q: Why choose us?

A: 1. Lowest factory price with good quality. 2. Low MOQ. 3. On-time delivery. 4. Welcome to visit our factory ,our machine and our workshop will help us speak more.

Advantages

1.We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

2.The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification).

3.The company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

4.The company adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers. The company also sets up a professional team for new product development, design, mold manufacturing, trial production, testing and inspection to provide customers with technical development and support services.

About JWHEEL

Guangdong Guangchuan Auto Parts Trading has its first plant established in 1993. After over 29 years’ development, Guangchuan Auto Parts Trading has become a world-leading supplier for many international famous wheel brands. Guangchuan Auto Parts Trading has an annual production capacity of 1.5 million and it provides one-stop solution for design and manufacturing. It’s equipped with advanced production facilities such as aluminum alloy melting furnace, casting production line, spinning and forging equipment, automatic painting line, helium leak detection system and automatic dynamic balance inspection system.

(For more information, just go to the website: https://www.jjjwheel.com)