High Quality Customized Gravity Cast - ODM Casting Service Supplier JWHEEL for Car Wheel

The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification), Translated with www.DeepL.com/Translator (free version).

Gravity casting is a method of manufacturing a cast wheel of an specific metal alloy, typically aluminum, although Magnesium is also used, which involves supplying molten metal to a mould cavity via a feeder through a running system where the molten metal entry point is located above the top of the mould cavity. In this manufacturing process all the metal entering the mould is subject to turbulence. This turbulence can cause severe defects such as oxide inclusions and entrapped gas porosity and in some cases mould erosion and hotspots.

https://www.jjjwheel.com

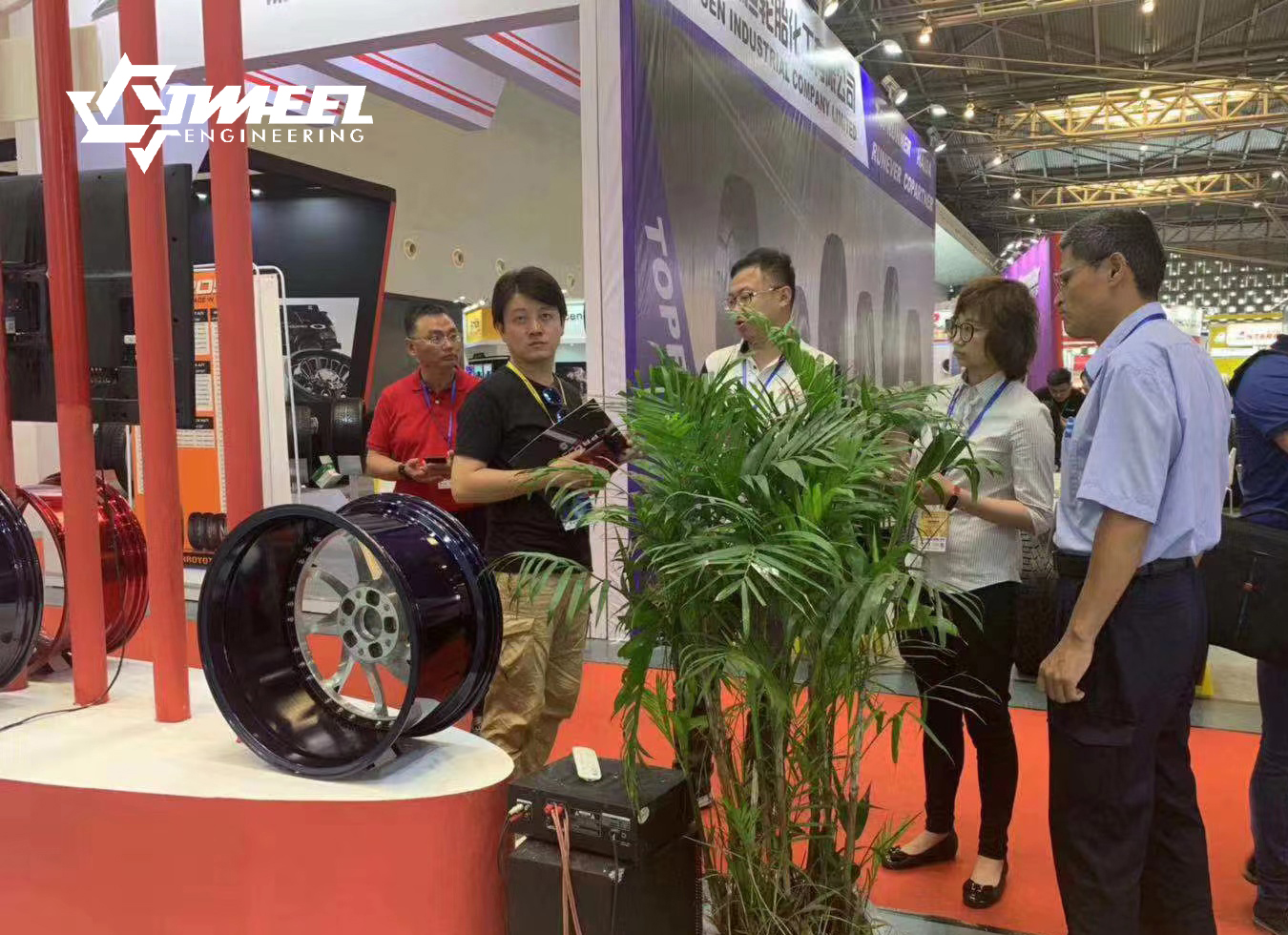

After years of solid and rapid development, JWHEEL has grown into one of the most professional and influential enterprises in China. cast rims We have been investing a lot in the product R&D, which turns out to be effective that we have developed cast rims. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.Because of the features of cast rims becomes most people's choice.

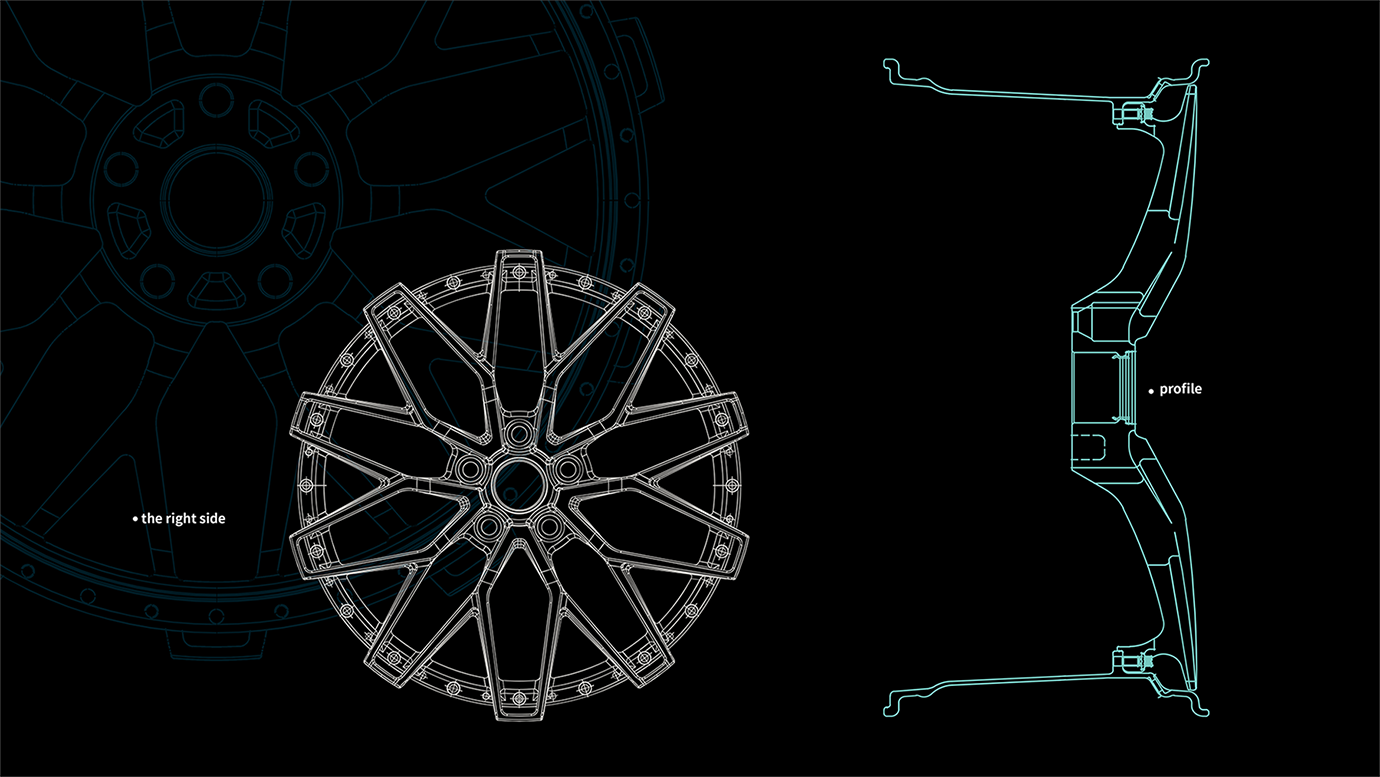

The ET value is the Off-set value, the deviation of the wheel mounting surface from the center line of the wheel rim. Off-set is defined as the distance between the rim's mounting surface and the center of the rim, with Positive Offset in the outward direction and Negative Offset in the inward direction of the rim.

PCD is the pitch center diameter, which is the diameter of the circumference of the CIRCLE centered on the wheel and surrounded by several screw holes, as well as the number of the holes

Spoke is a device to protect the wheel rim and spokes of the vehicle wheel, the diameter size of the cover plate is close to the diameter size of the wheel rim, the center of the cover plate has a hole larger than the wheel rotation axis, and there is a hole in the part of the cover plate near the edge, and the edge of the cover plate has a ring-shaped wheel plate, and the surface of the wheel plate can fit closely with the surface of the wheel rim

The rim, commonly known as the wheel rim, is the part of the wheel around which the tire is mounted. Its nominal width and nominal diameter are expressed in inches. The linkage symbol in the middle (* or -) indicates whether the rim is integral or not.

Polish:

Gross Black

Polish:

Matte Black

Polish:

Flash Silver Gun Metal

Polish:

Tanzannian sapphire blue

Polish:

Gross Bronze

Brush:

Candy Red Clear Coat

Brush:

Brown Clear Coat

Brush:

Blue Clear Coat

Brush:

Bronze Clear Coat

Brush:

Blue Black Clear Coat

Our Advantages

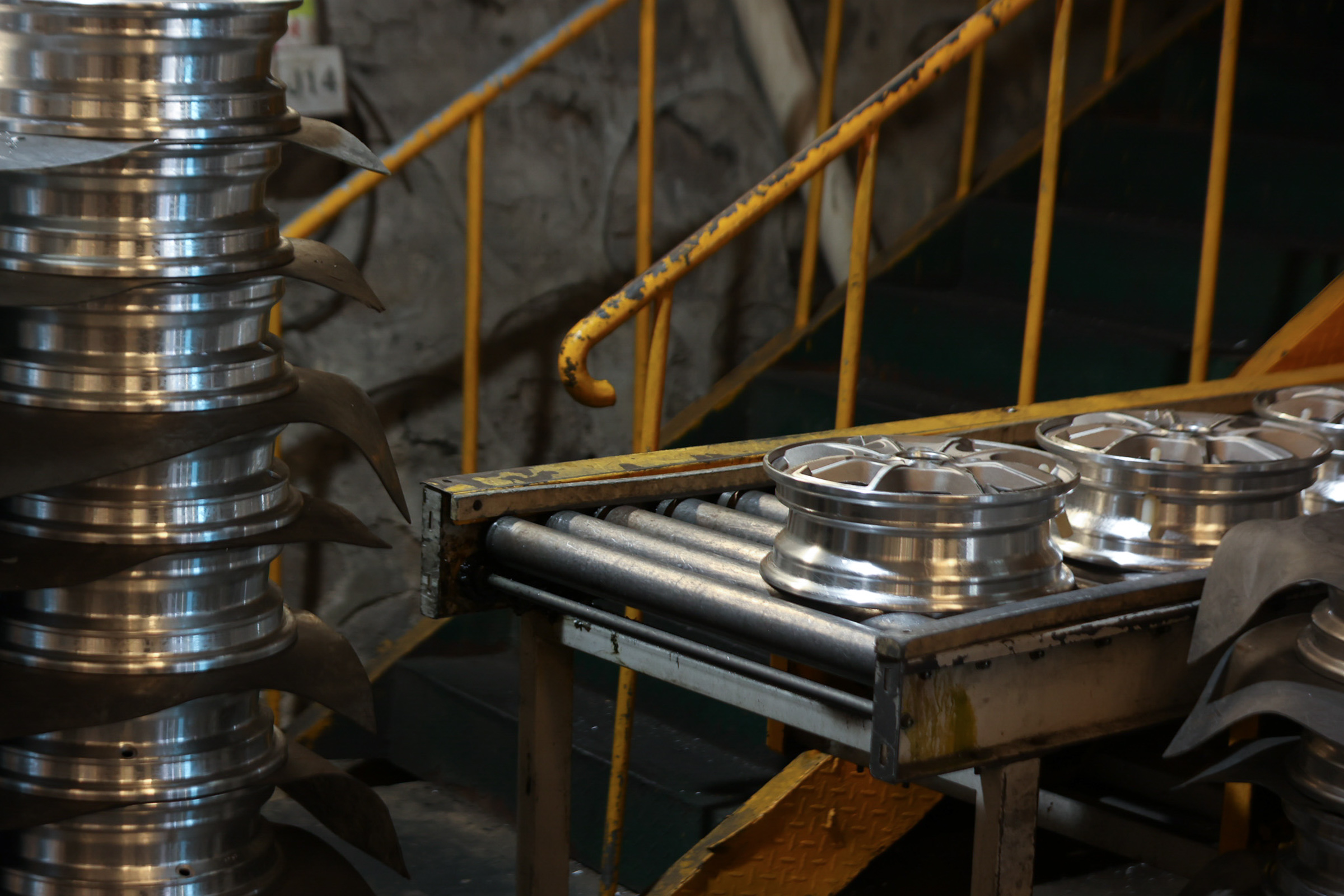

1. Large production capacity:12000 Pieces per Day

2. Very competitive prices: We are always aim to occupy more marketing under best reasonable pricing.

3. Strict Quality Control: Our QC operation is strictly conducted in ISO9001, to ensure the good quality items to our customers.

4. High product consistency:Large-scale automated production.

5. Company development: company develops steadily, has 30 years’history.

6. We can provide you with all types of wheels and accessories without any intermediary, which means lowest costs and competitive price in the market.

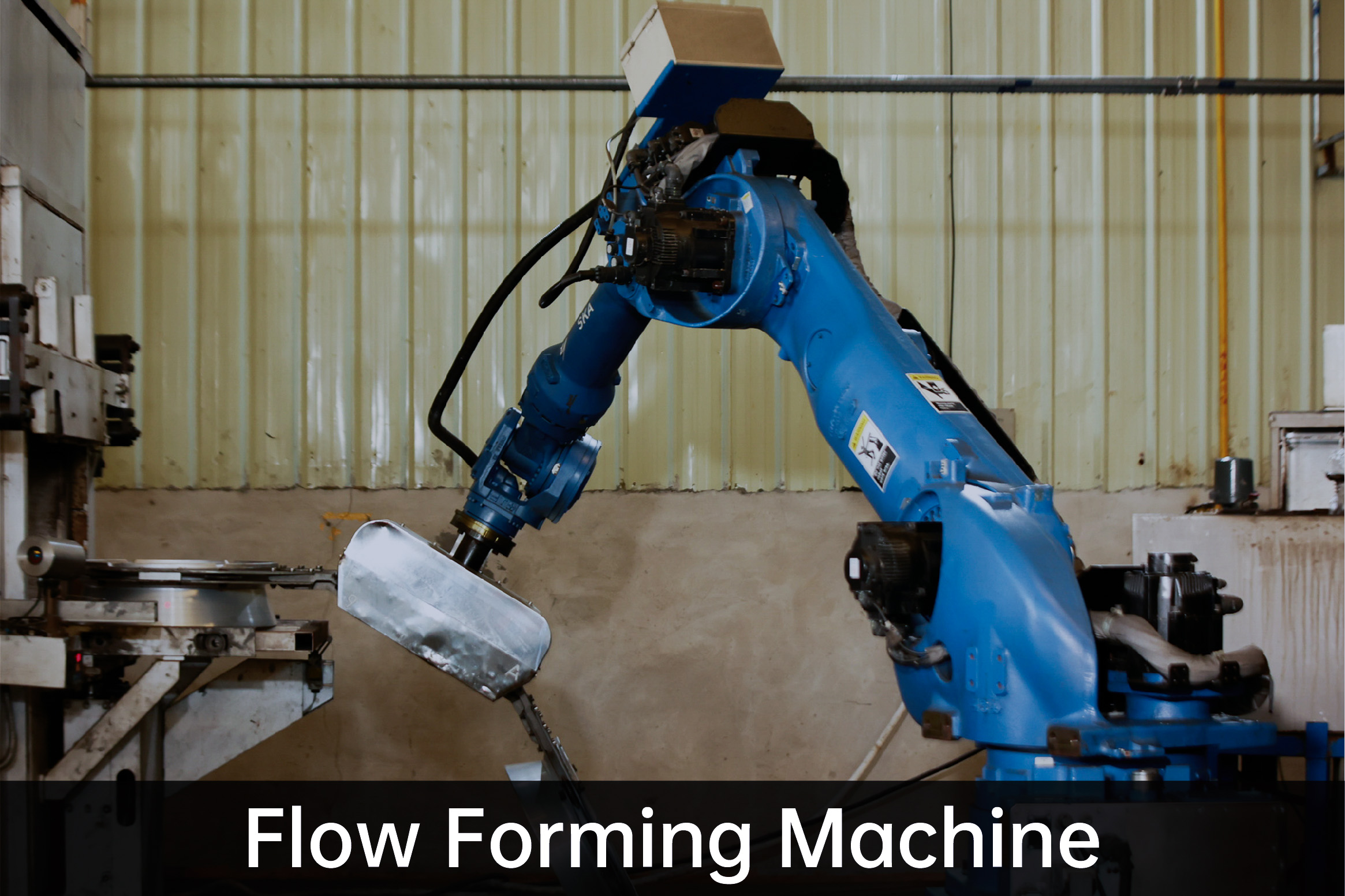

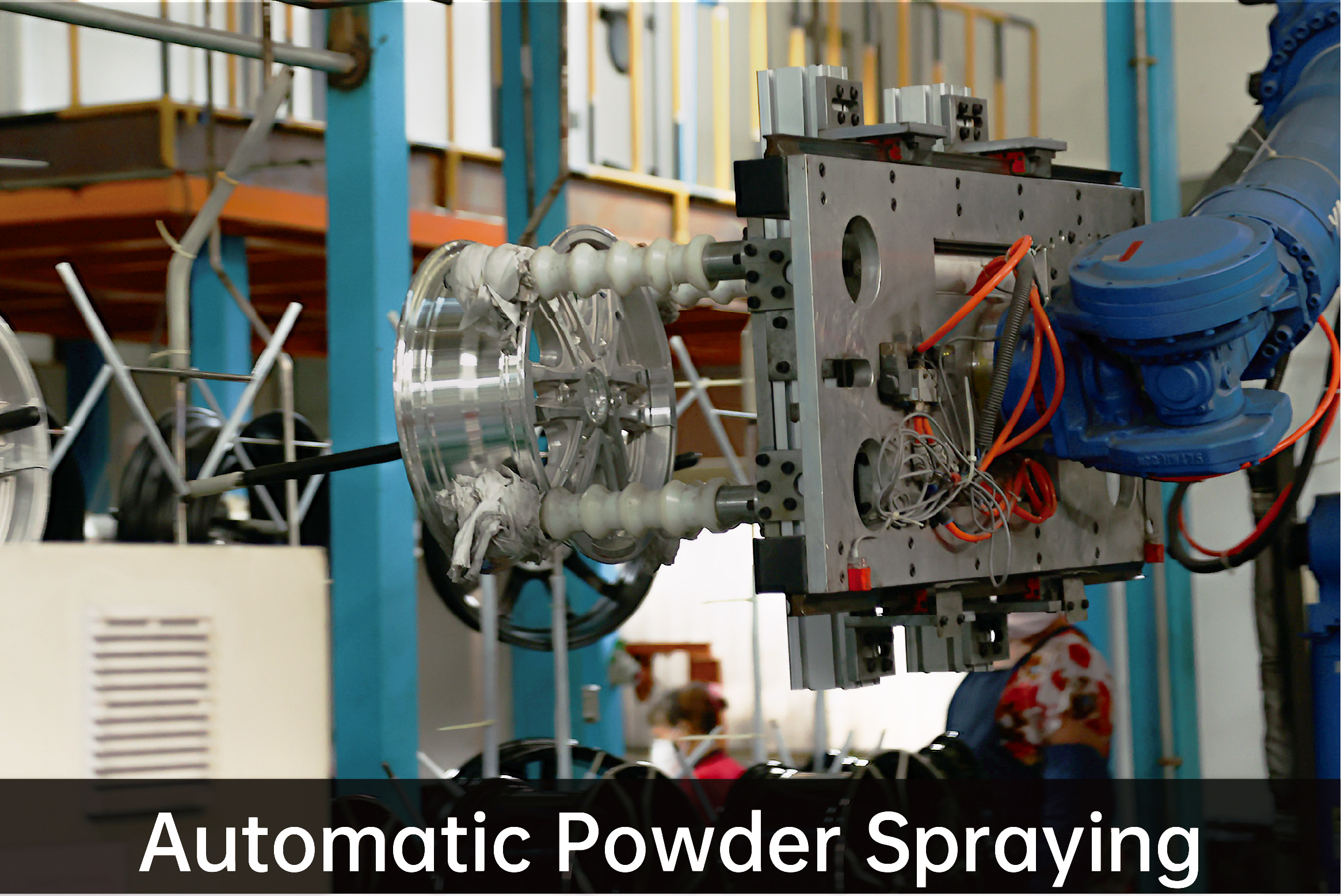

7. We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

8. The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

9. Our company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

10. Our company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association ce

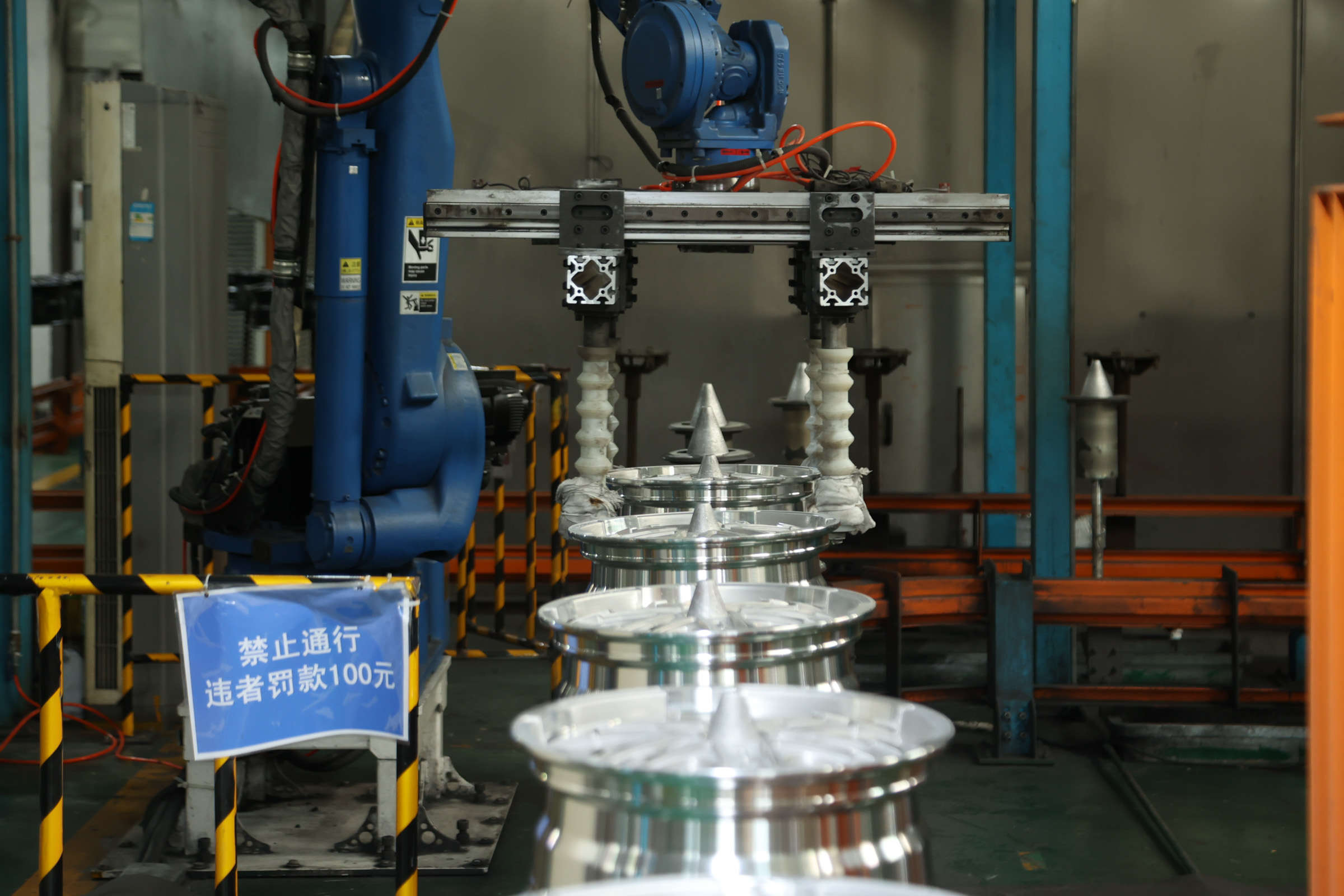

JWHEEL adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers.

Full automatic wheel run out/dynamic balance testing line, suitable for wheel run out and dynamic balance detection.

Run out test: measure the size and phase of the inner and outer radial and axial run out of the wheel.

Dynamic balance test: measure the size and phase of unbalance on both sides.

The lower the flat ratio of the tire, the higher the standard of impact resistance of the wheel. The lower the flat ratio, the greater the impact of the road towards the rim. In response to these changes, JWHEEL uses 30°and 13° impact tests to measure the wheel. (That is, radial impact test is to strike the barrel with a certain hammer weight ).

The 13° impact test mainly uses a heavy hammer to impact the part where the wheel edge connected with the tire at an Angle of 13°, so as to simulate the impact that the car may go through while running on the road, for example rocks or the edge of the road. There are two criteria to measure whether the wheel should be accepted : Spokes should not have penetrating cracks, and the tire should not be completely separated from the barrel within 30 seconds.

Salt spray test is a test that examines the corrosion resistance of the products or metal materials. It uses a salt spray test equipment that creates salt spray environment conditions to detect whether the coating of the wheel is stable, and will there be paint drop, electroplating fade, or cracking, etc.

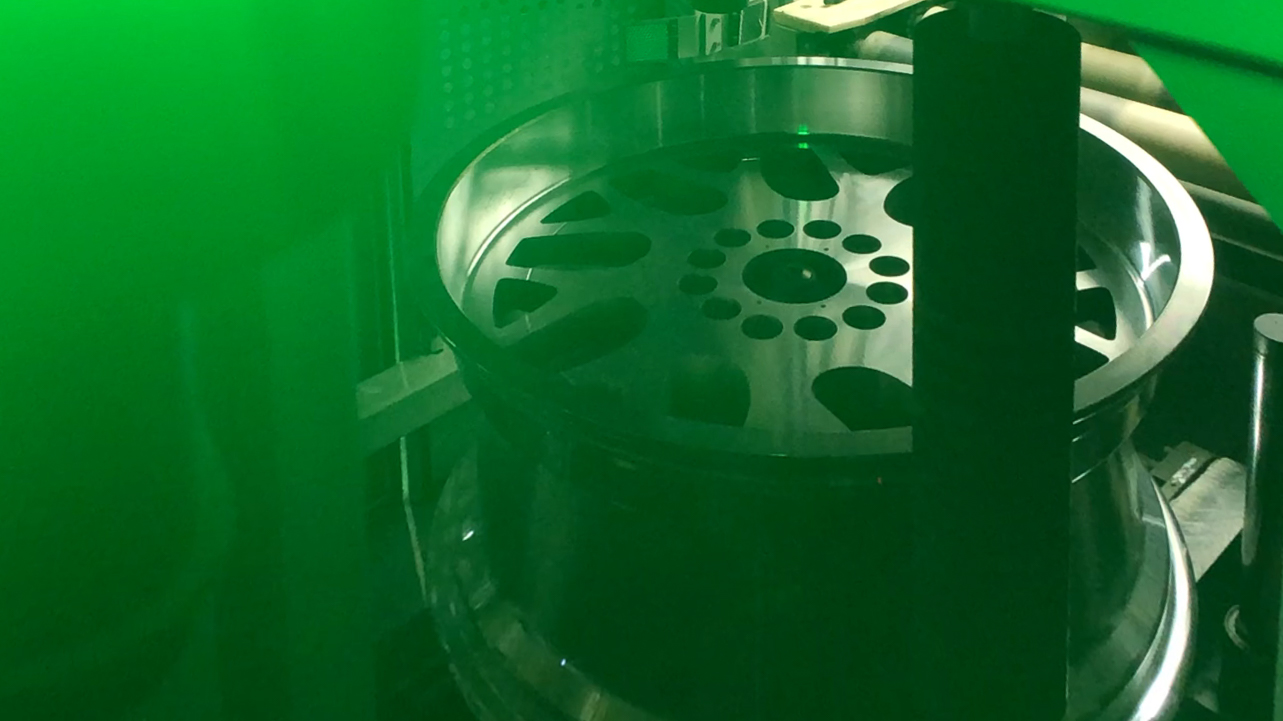

Helium mass spectrometer is used to detect the leakage of the hub. Helium gas is used as the tracer gas. Different masses of gas will be separated according to the mass charge ratio in the mass spectrometry chamber of the mass spectrometer. Then the mass spectrogram of the tracer gas can be obtained, and the hub leakage rate can also be obtained safely, quantitatively and quickly.

Water tightness test - bubble leak detection method. Its detection principle is to close the inner and outer side of the aluminum alloy wheel with sealing disk through external force, and then immerse the wheel and sealing disk in water, as the aluminum alloy wheel is closed, a part of the gas is compressed, resulting in the increase of the pressure of the inner cavity of the wheel. If the wheel rim has a leak hole, the compressed gas will leak out from the leak hole and form bubbles in the water.

No matter what kind of manufacturing method is applied, we can not completely avoid the defects that may be created during the production process. JWHEEL company will find out any unqualified hubs by X-ray detection and then do the recasting. Only 100% good hubs will be moved into the next production process.

The wheel, as a high-speed moving and weight support part of a vehicle, has a vital relation with the safety performance of the whole vehicle and the safety of drivers and passengers. Therefore Jwheel attaches great importance to the hub quality.

There are a series of reasons that may cause casting wheel defects. Such as not strict enough raw material control, unreasonable production process, unreasonable mold structure design, etc. Casting defects includes bubbles, pores, inclusions and looseness, etc. As the internal defects cannot be identified by naked eyes, X-ray becomes a good way to detect the internal quality of the wheel.

Bending test is to determine the solidity of the rim and spoke by simulating the stress on the wheel when the vehicle is shaking. The whole wheel is subjected to a rotational bending force. The load of the wheel in the test varies from 500 kg to 720 kg depending on the wheel parameters, and the number of rotations is not less than 100,000 revolutions according to industry standards. For the appearance of any of the following three phenomena, the test will be determined failed. (1) the wheel can not continue to bear the load (2) New visible cracks appear in any part of the wheel (3) Before reaching the required number of cycles, the offset of the loading point has exceeded 10% of the initial loading.

The radial fatigue test simulates road conditions while driving. Install the hub to the tire to run for 500,000 or even 1,000,000 rotations on the test platform.

The company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association certification (laboratory certification).

Gravity casting is a method of manufacturing a cast wheel of an specific metal alloy, typically aluminum, although Magnesium is also used, which involves supplying molten metal to a mould cavity via a feeder through a running system where the molten metal entry point is located above the top of the mould cavity. In this manufacturing process all the metal entering the mould is subject to turbulence. This turbulence can cause severe defects such as oxide inclusions and entrapped gas porosity and in some cases mould erosion and hotspots.