JWHEEL has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product forge auto rims will bring you a lot of benefits. We are always standby to receive your inquiry. forge auto rims If you are interested in our new product forge auto rims and others, welcome you to contact us.By optimizing the quality of forge auto rims, JWHEEL has been more popular than before.

| Model | Size | Offset(mm) | PCD(mm) | Center hole CB(mm) | Color | Weight(KG) |

| J1F086-20 | 20X9 | 35 | 112*5H | 66.6 | Silver + Glossy + Finish(MS42AP) | 11.3 |

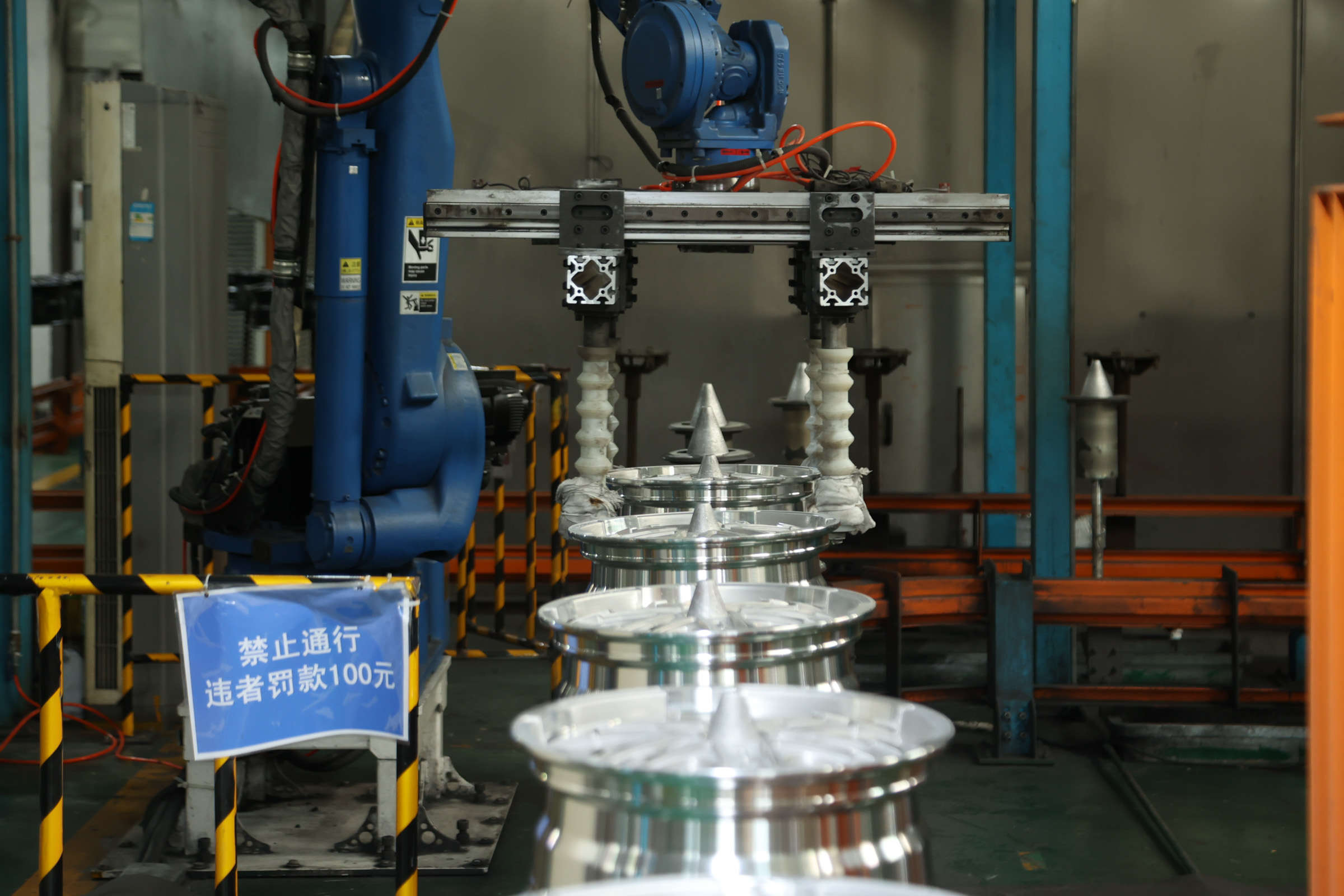

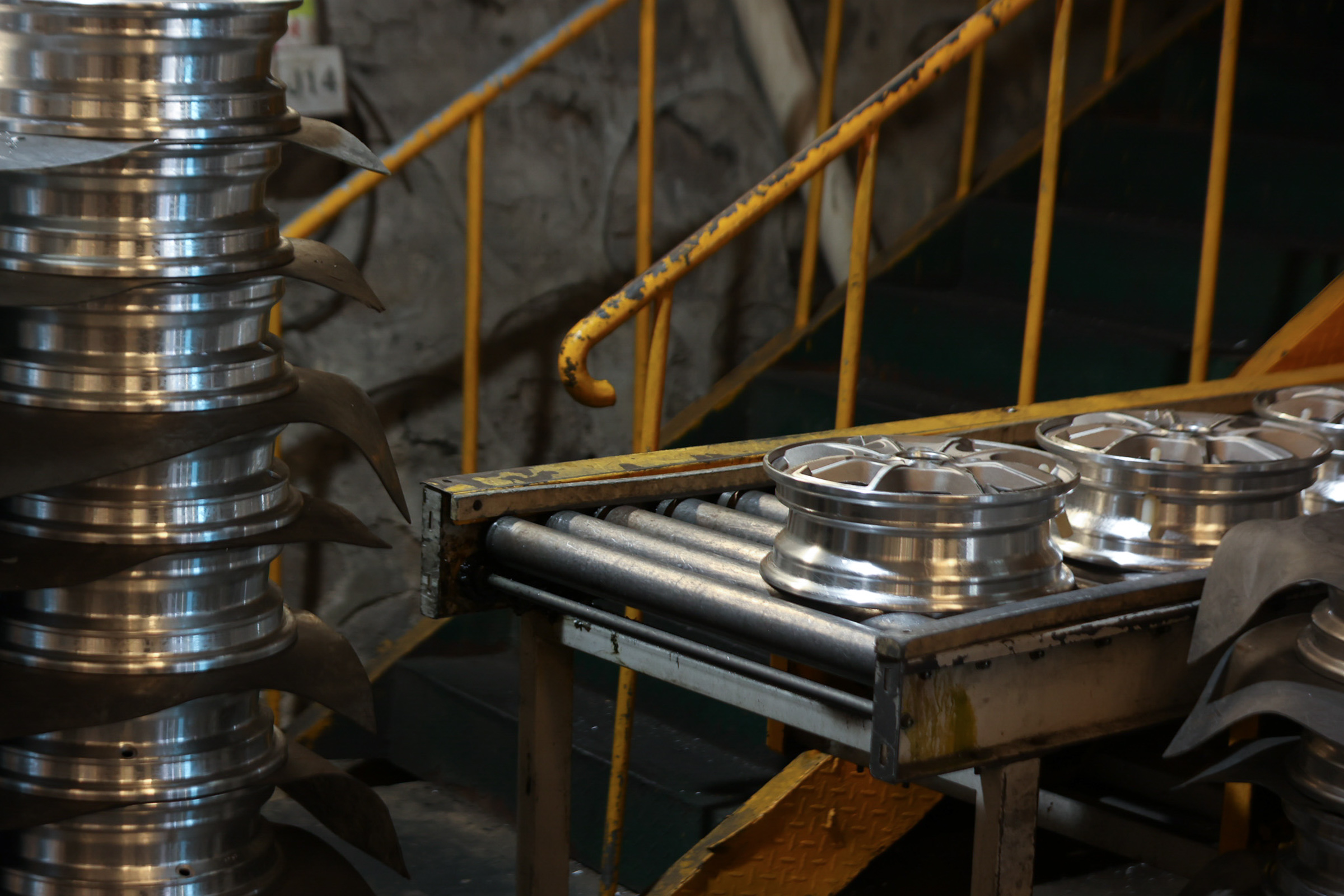

Production process

One Piece Forged Wheels

Custom Products

For 20X9 performance cars

Material

Made in 6061 aluminum alloy

Color

Silver + Glossy + Finish(MS42AP)

Surface Process

Fully coated high gloss silver,brushed

Design Features

Multi-spoke V-shaped design, fully coated with high-gloss silver, brushed for a more premium look.

Polish:

Gross Black

Polish:

Matte Black

Polish:

Flash Silver Gun Metal

Polish:

Tanzannian sapphire blue

Polish:

Gross Bronze

Brush:

Candy Red Clear Coat

Brush:

Brown Clear Coat

Brush:

Blue Clear Coat

Brush:

Bronze Clear Coat

Brush:

Blue Black Clear Coat

Our Advantages

1. Large production capacity:12000 Pieces per Day

2. Very competitive prices: We are always aim to occupy more marketing under best reasonable pricing.

3. Strict Quality Control: Our QC operation is strictly conducted in ISO9001, to ensure the good quality items to our customers.

4. High product consistency:Large-scale automated production.

5. Company development: company develops steadily, has 30 years’history.

6. We can provide you with all types of wheels and accessories without any intermediary, which means lowest costs and competitive price in the market.

7. We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

8. The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

9. Our company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

10. Our company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association ce

Regarding the attributes and functionality of the forge auto rims, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing forge auto rims organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. forge auto rims QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the forge auto rims, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Guangdong Guangchuan Auto Parts Trading Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

In China, ordinary working time is 40 hours for employees who work full time. In Guangdong Guangchuan Auto Parts Trading Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Forged Wheels and an unforgettable experience of partnering with us.