At JWHEEL, technology improvement and innovation are our core advantages. Since established, we have been focusing on developing new products, improving product quality, and serving customers. flow forged wheels Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product flow forged wheels or our company, feel free to contact us. has established long-term strategic partnerships with several well-known brands of flow forged wheels.

| Model | Size | Offset(mm) | PCD(mm) | Center hole CB(mm) | Color | Weight(KG) |

| J282-13 | 13x4 | 43 | 100*4H | 67.1 | F5U03+F5C/C68 | 6.32 |

| J282-14 | 14x4.5 | 43 | 100*4H | 67.1 | F5U03+F5C/C68 | 8 |

| J282-15 | 15x4.5 | 43 | 100*4H | 67.1/64 | F5U03+F5C/C68 | 8.85 |

| J282-16 | 16x7 | 28/35 | 114.3*5H | 73.1 | F5U03+F5C/C68 | 11.85 |

| J282-17 | 17x8 | 20/35/38 | 114.3/127/139.7*5H/6H | 73.1/106.2 | F5U03+F5C/C68 | 14 |

Production process

Low-pressure casting wheels

Custom Products

Multi-size urban off-road style

Material

Made in A356 aluminum alloy

Color

Black, gunmetal grey

Surface Process

Fully coated process, two-colour process

Design Features

Home off-road, urban off-road style, false two-piece, cost-effective

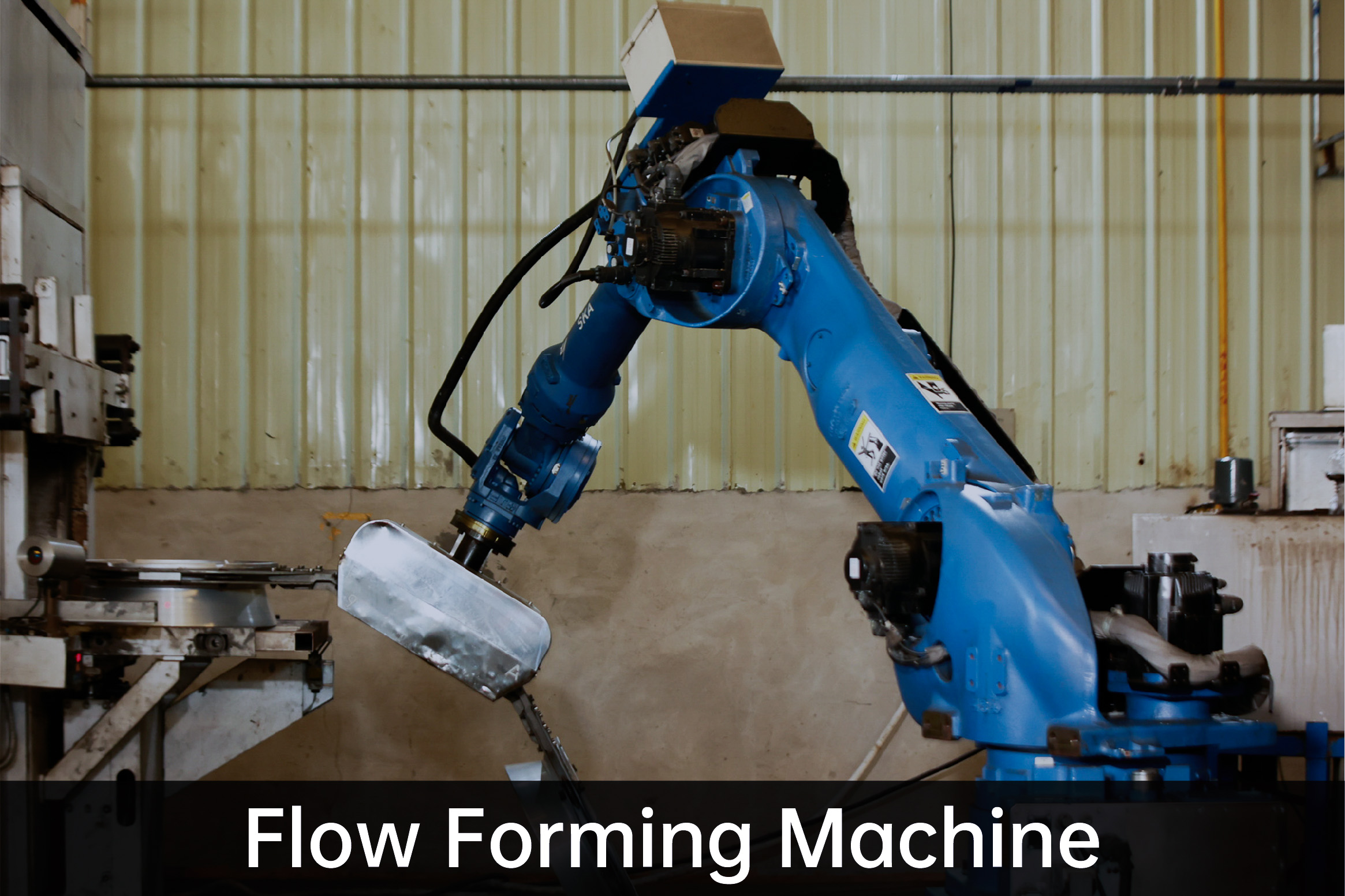

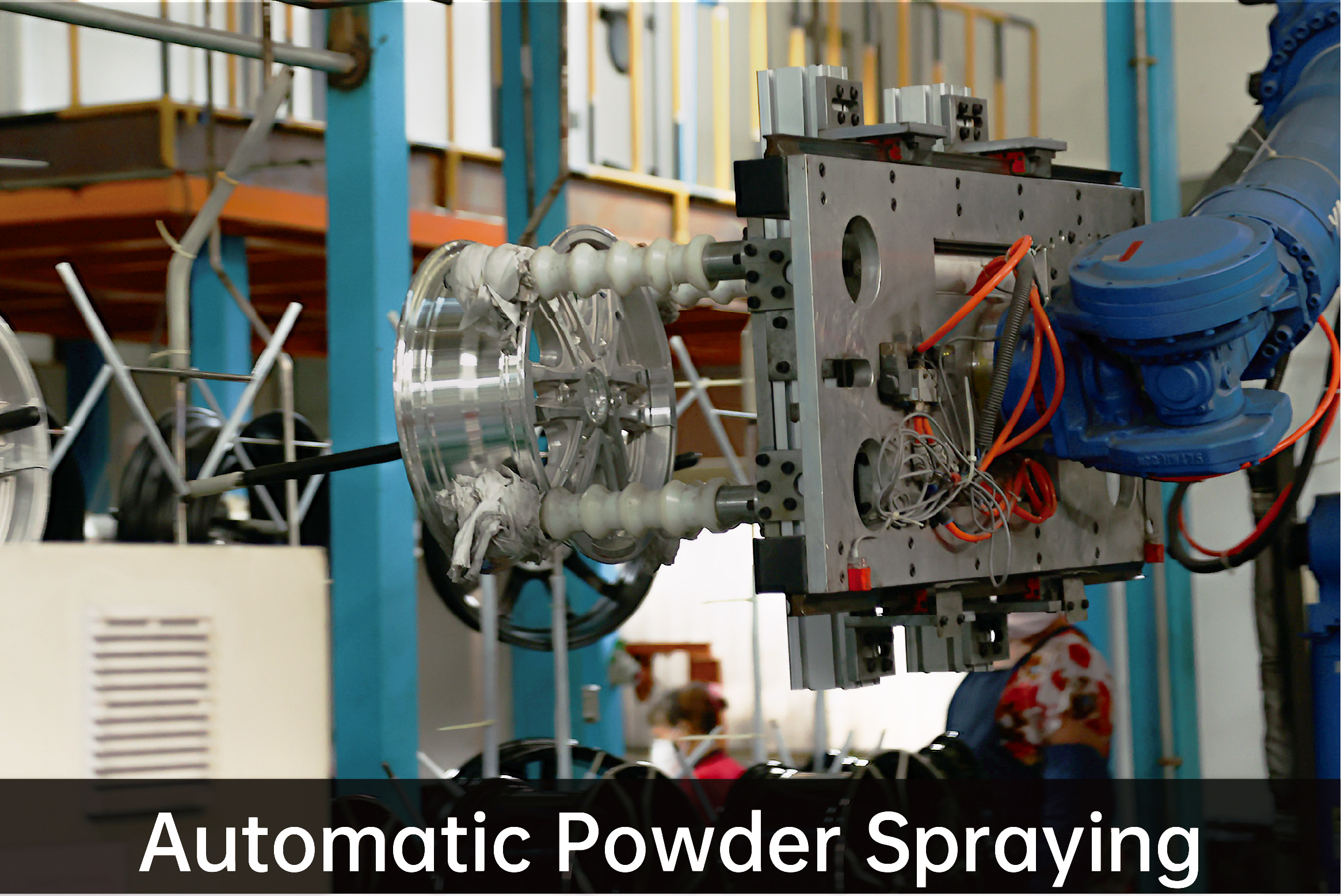

JWHEEL adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. flow forged wheels QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In essence, a long-standing flow forged wheels organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Guangdong Guangchuan Auto Parts Trading Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of flow forged wheels come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

In China, ordinary working time is 40 hours for employees who work full time. In Guangdong Guangchuan Auto Parts Trading Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Flow Formed Wheel and an unforgettable experience of partnering with us.