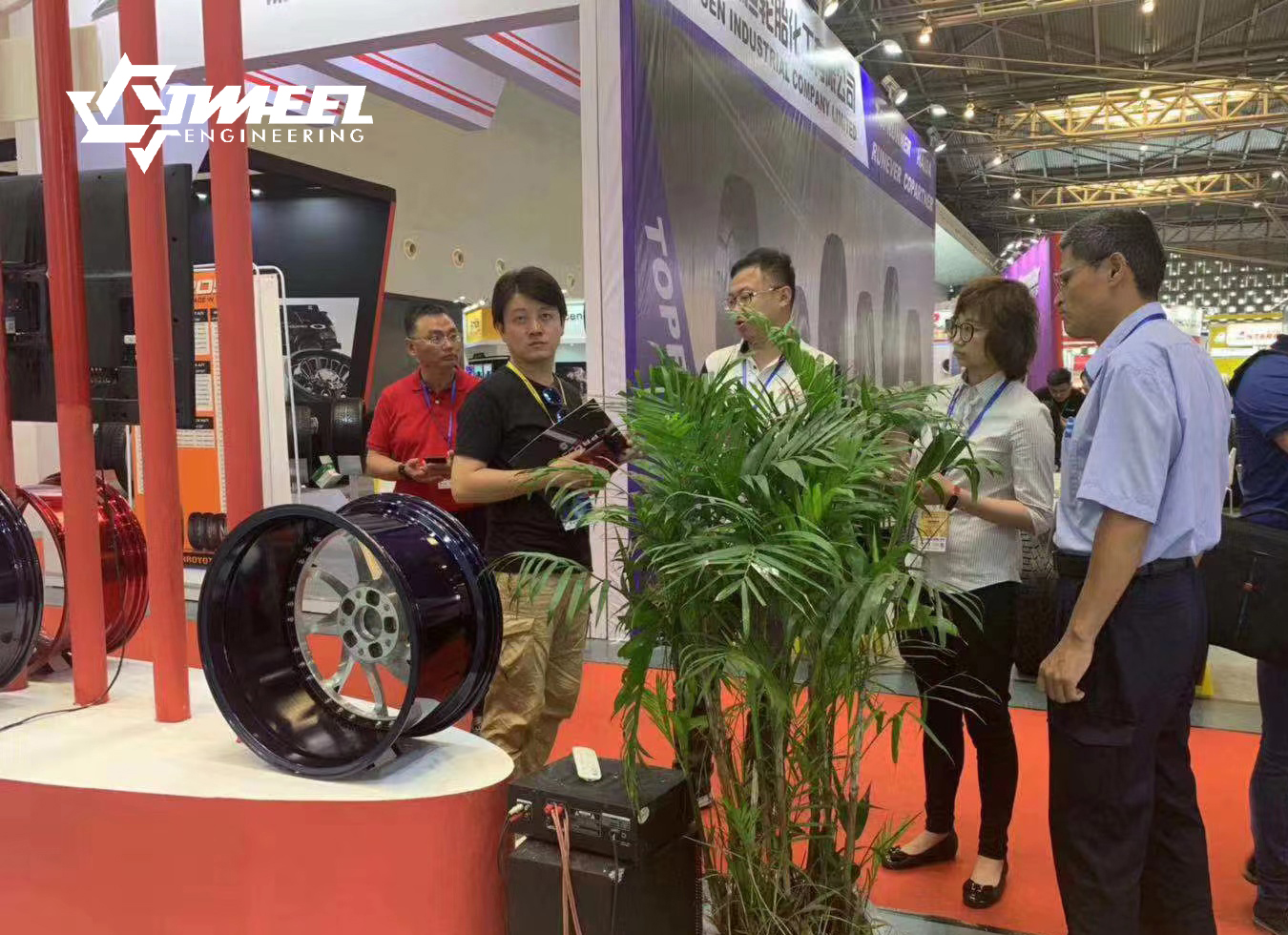

Unleash the Power of Elegance: China's Premier High-gloss Black & Metallic Wheels Provider! compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.JWHEEL summarizes the defects of past products, and continuously improves them. The specifications of Unleash the Power of Elegance: China's Premier High-gloss Black & Metallic Wheels Provider! can be customized according to your needs.

Customized High-gloss black, face, metallic paint, multi-spoke wheels manufacturers From China |.

The product has good bendability. Made of materials that feature high flex fatigue, it is not easy to deform or crack when posed with pressure.

🌟 Experience Unmatched Elegance! Introducing China's leading supplier of High-gloss Black & Metallic Wheels – igniting your vehicle's style like never before! 🔥 Unleash a dynamic revolution on the road, with wheels that radiate pure sophistication and power. Don't settle for ordinary, elevate your ride to extraordinary! 💫 #HighGlossFinishes #MetallicWheels #UnleashElegance #RevampYourRide

SEND INQUIRY NOW

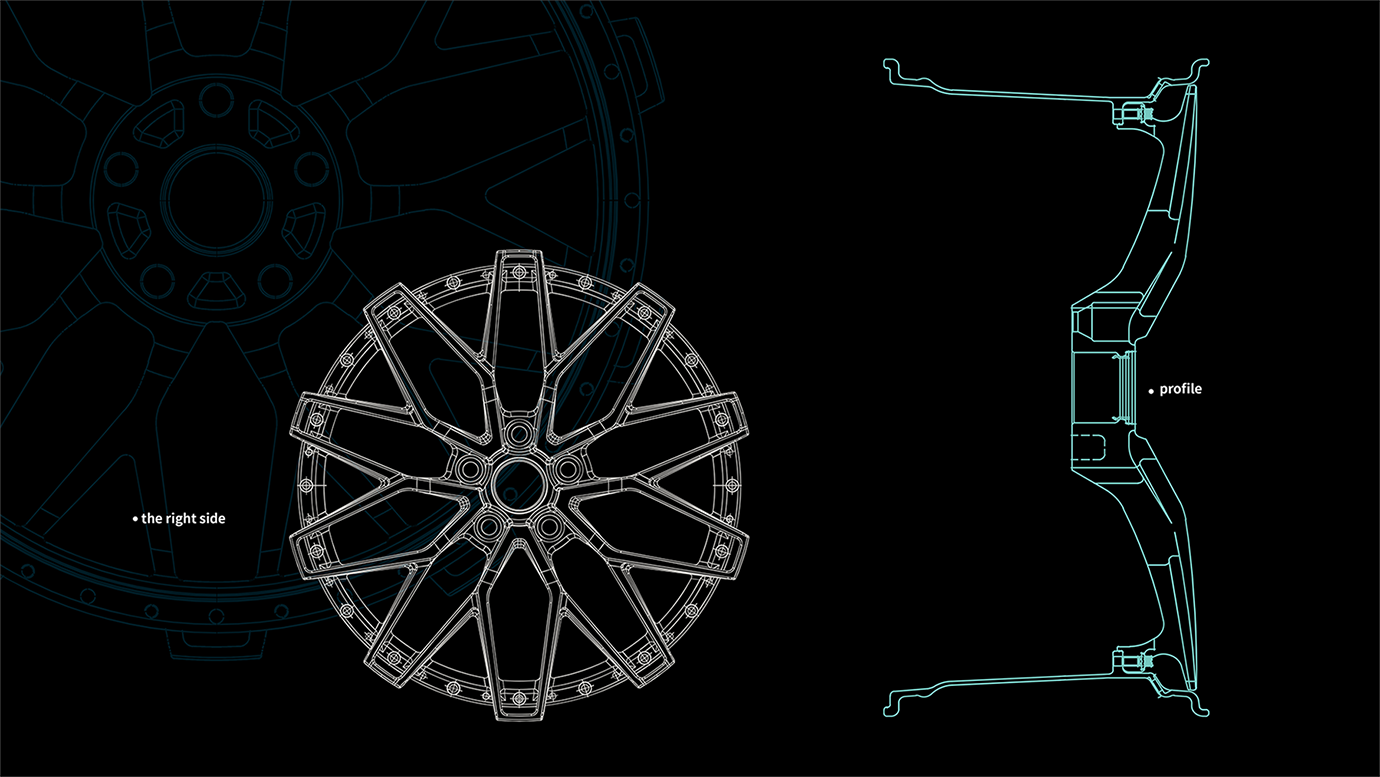

Model: J274

MOQ: 300 pieces

Size:

17x7

18x8.5

19x8.5

PCD(mm): 105-114.3*5H

Offset(mm): 35-50

Center hole CB(mm): 71.58/82.05

Color Colour: GM21/MGM33AP/GM20

Custom Products: All wheels unpainted

| Model | Size | Offset(mm) | PCD(mm) | Center hole CB(mm) | Color | Weight(KG) |

| J274-17 | 17x7 | 35-47 | 105-114.3*5H | 56.6/82.05 | GM21/MGM33AP/GM20 | 9.15 |

| J274-18 | 18x8.5 | 35-50 | 108-130*5H | 71.58/82.05 | S92 | 12.05 |

| J274-19 | 19x8.5 | 35-47 | 108-120*5H | 82.05 | S92 | 12.85 |

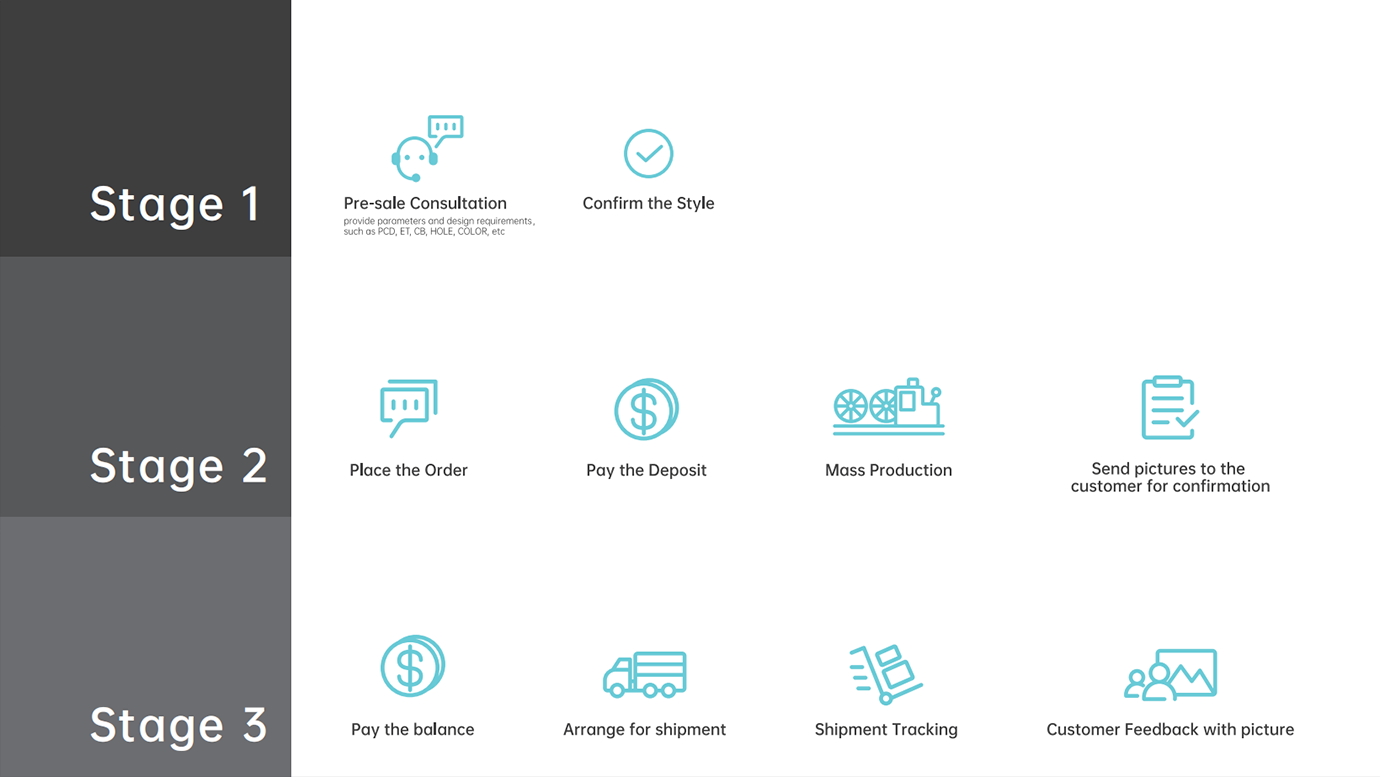

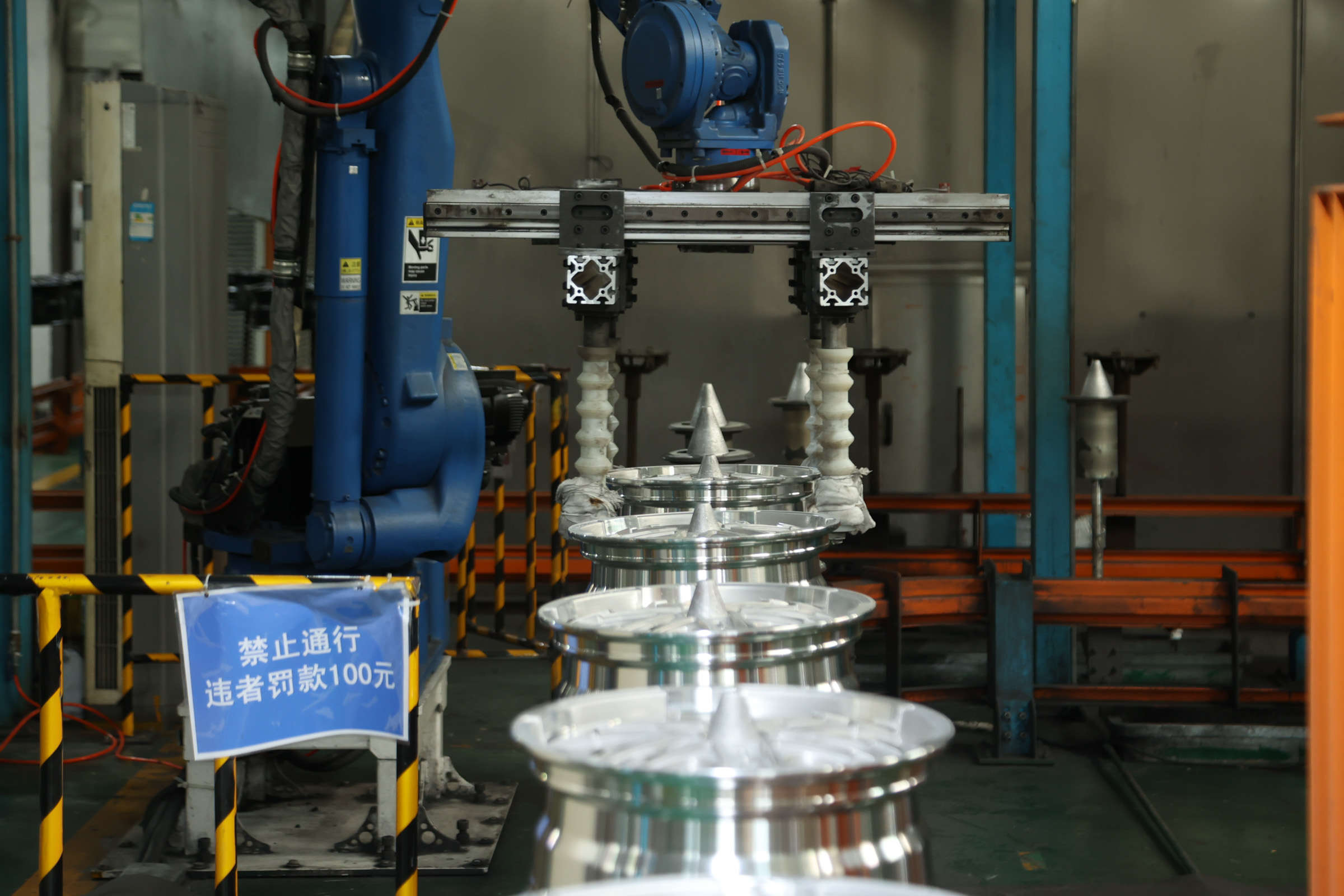

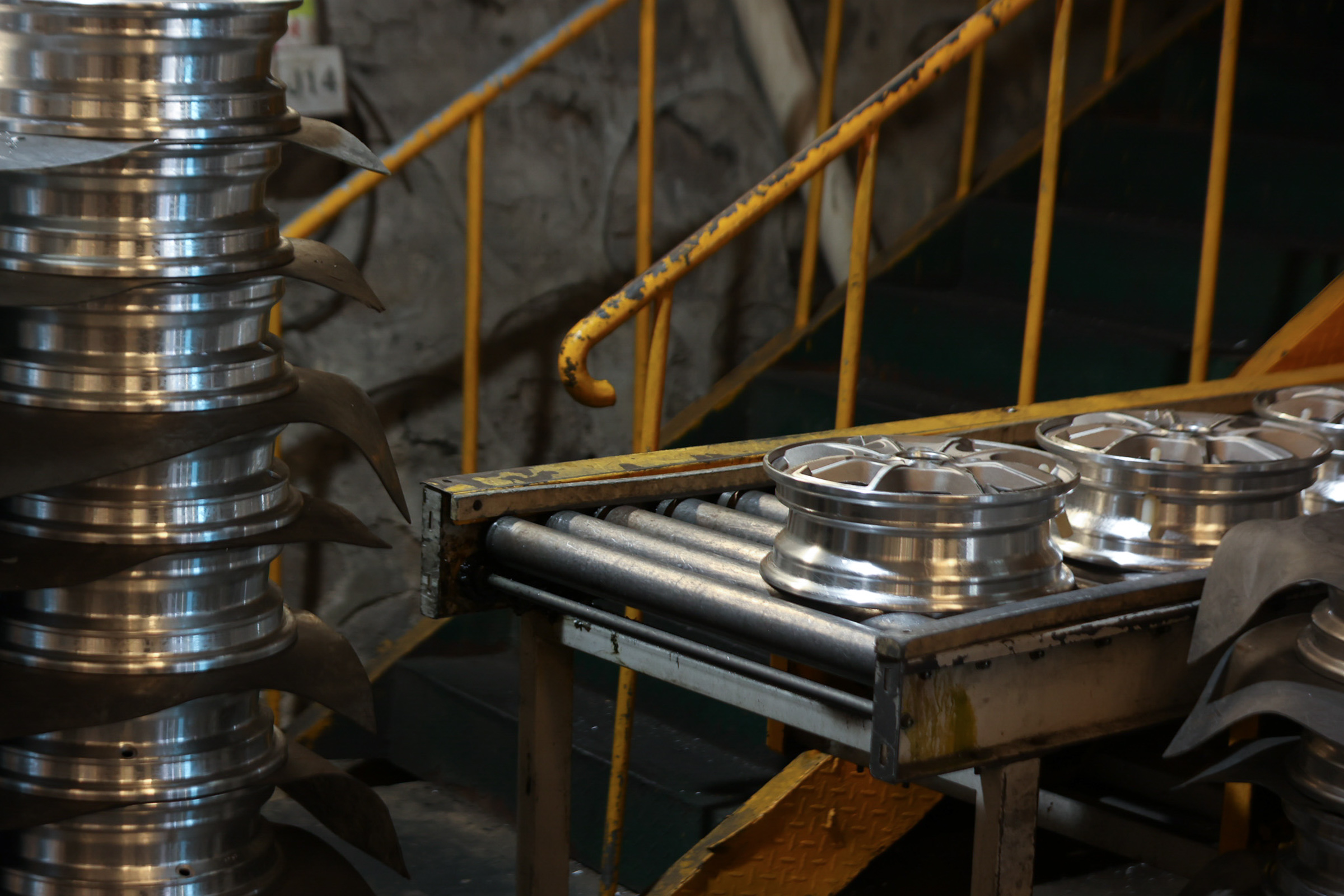

Production process

Low-pressure casting wheels

Custom Products

German car selection style, Mercedes Benz, BMW, Audi, Volkswagen

Material

Made in A356 aluminum alloy

Color

Gloss Black, Gunmetal Gray, Full Coat Process

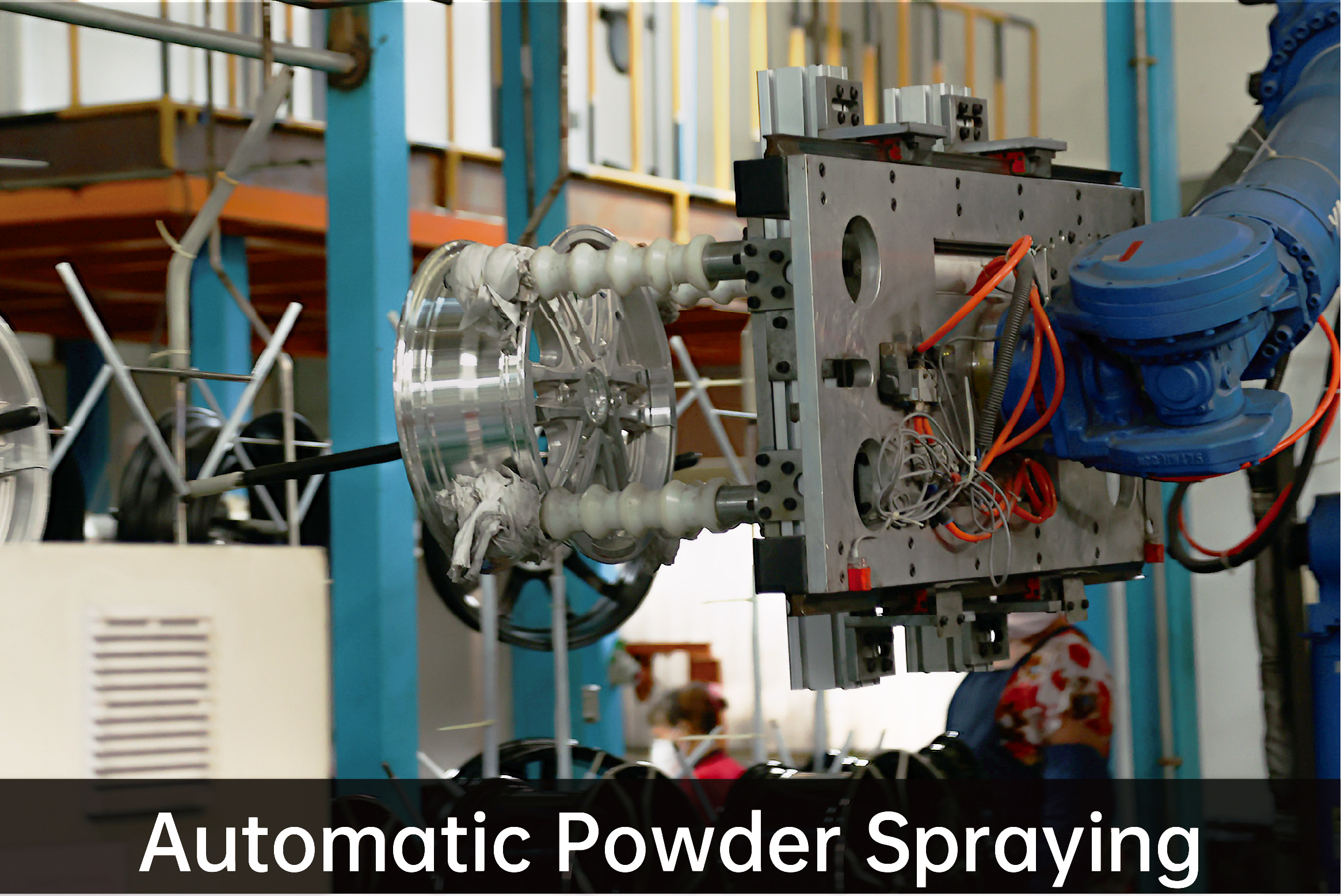

Surface Process

Surface treatment, brushed

Design Features

Multi-spoke, sharp, slightly raised in the center, expanding outward in a claw pattern

Our Advantages

1. Large production capacity:12000 Pieces per Day

2. Very competitive prices: We are always aim to occupy more marketing under best reasonable pricing.

3. Strict Quality Control: Our QC operation is strictly conducted in ISO9001, to ensure the good quality items to our customers.

4. High product consistency:Large-scale automated production.

5. Company development: company develops steadily, has 30 years’history.

6. We can provide you with all types of wheels and accessories without any intermediary, which means lowest costs and competitive price in the market.

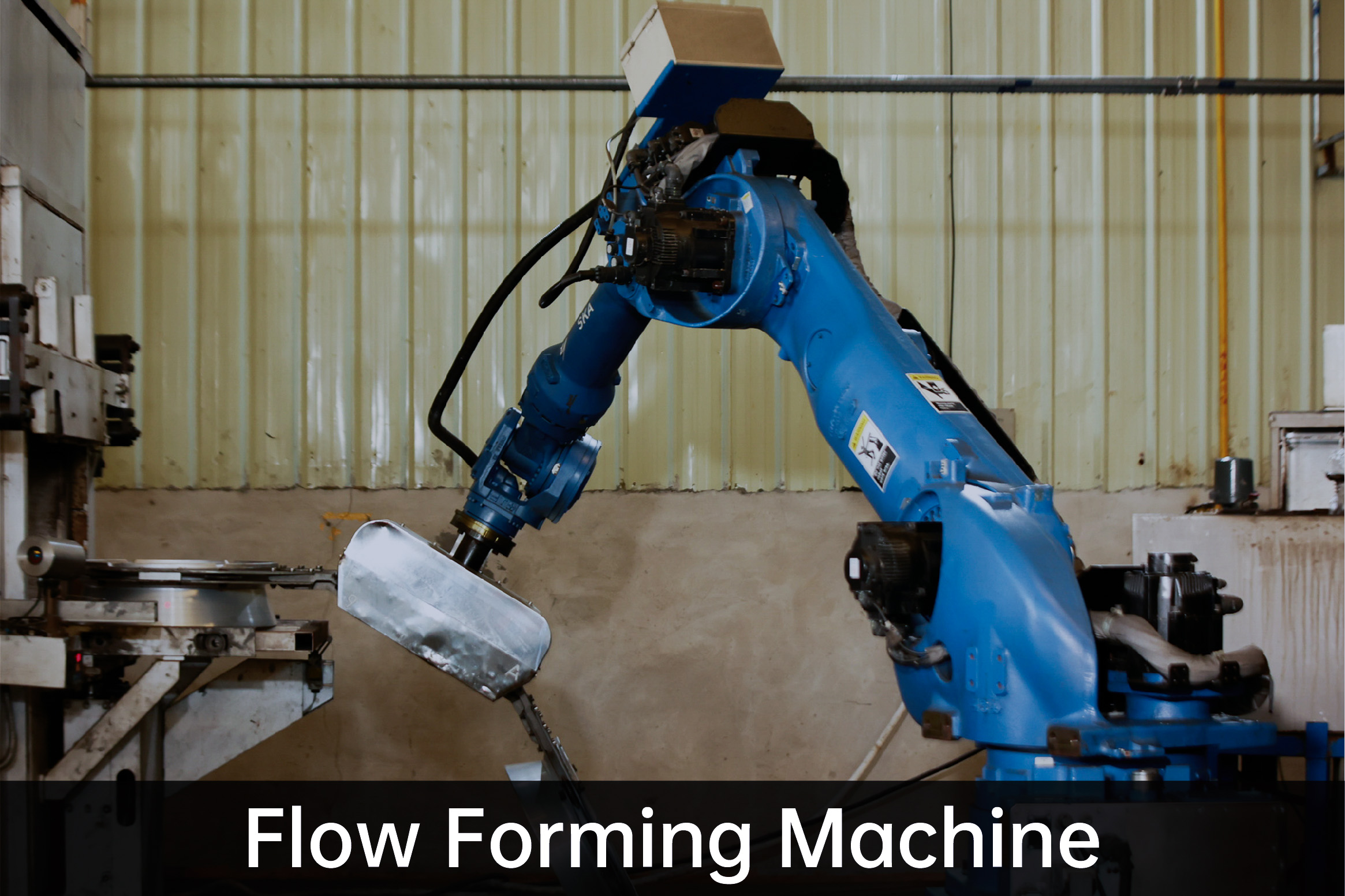

7. We not only have the traditional low-pressure casting technology, but also have the high strength and light weight manufacturing technology of "low-pressure casting + spinning". We always maintain various advanced technology advantages in aluminum alloy wheel manufacturing to meet customers' needs and lead the industry development.

8. The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

9. Our company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

10. Our company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association ce

JWHEEL adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers.

The radial fatigue test simulates road conditions while driving. Install the hub to the tire to run for 500,000 or even 1,000,000 rotations on the test platform.

Leave A Message