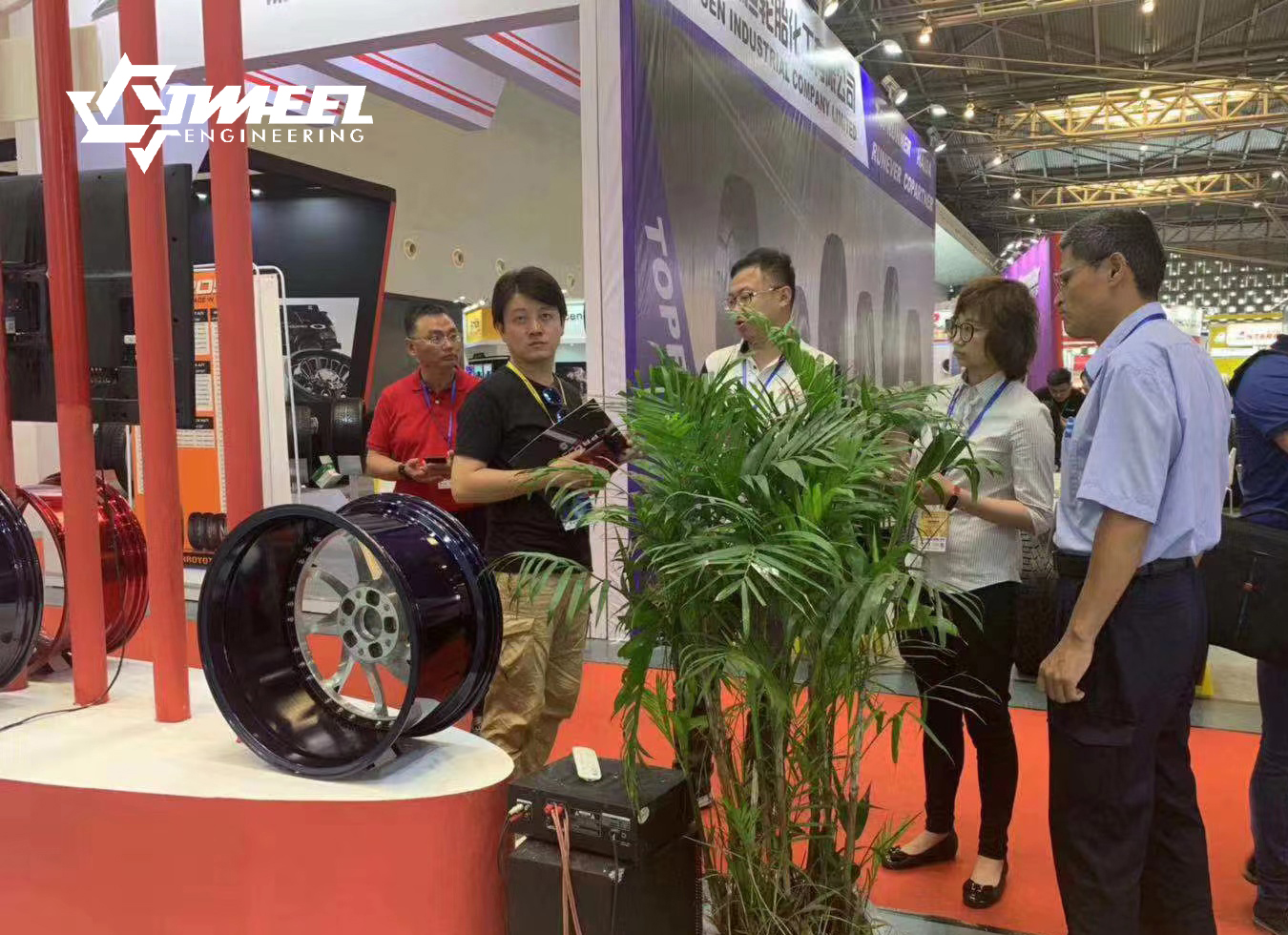

Unleash a Sleek Statement: High-Gloss Black Multi-Spoke Wheels! compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.JWHEEL summarizes the defects of past products, and continuously improves them. The specifications of Unleash a Sleek Statement: High-Gloss Black Multi-Spoke Wheels! can be customized according to your needs.

Multi-spoke face high-gloss black wheels Products |.

This product has passed through a rigorous testing and obtained certifications.

Rev up your style with a stunning set of wheels that demand attention! Introducing our latest obsession: High-Gloss Black Multi-Spoke Wheels. 💥 These sleek statements are the perfect way to elevate your ride to a whole new level of sophistication. 😍 Get ready to turn heads on the road with their mesmerizing shine and unparalleled design. 🔥 Don't miss out on the chance to make a bold statement – get your hands on these must-have wheels today! ✨ #WheelsOfSteel #SleekAndStylish #RideInStyle

SEND INQUIRY NOW

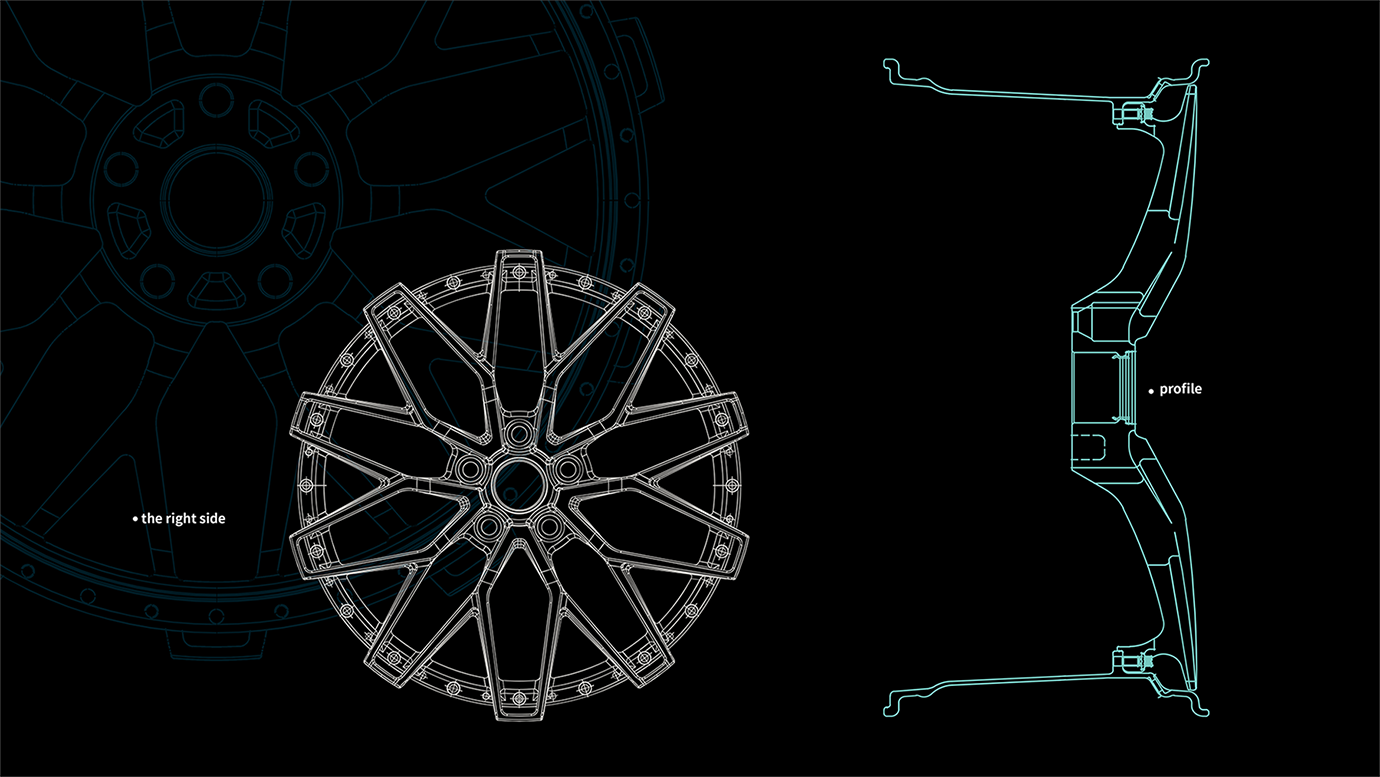

Model: J258

MOQ: 300 pieces

Size:

18X8

19x8.5

19X9.5

PCD(mm): 108-120*5H

Offset(mm): 35/38/42

Center hole CB(mm): 35/38/42

Color Colour: MUGM45AR/MUCAR/XMUGM33

Custom Products: All wheels unpainted

| Model | Size | Offset(mm) | PCD(mm) | Center hole CB(mm) | Color | Weight(KG) |

| J258-18 | 18X8 | 35/38/42 | 108-120*5H | 66.6/72.6/73.1 | MUGM45AR/MUCAR/XMUGM33 | 11 |

| J258-1912 | 19x8.5 | 45 | 108-120*5H | 66.6/72.6 | FGM45/MUCCP | 12.14 |

| 19X9.5 | 35/38/45 | 112-120*5H | 66.6/72.6/73.1 | FGM45/MUCCP/XMUGM33 | 12.52 |

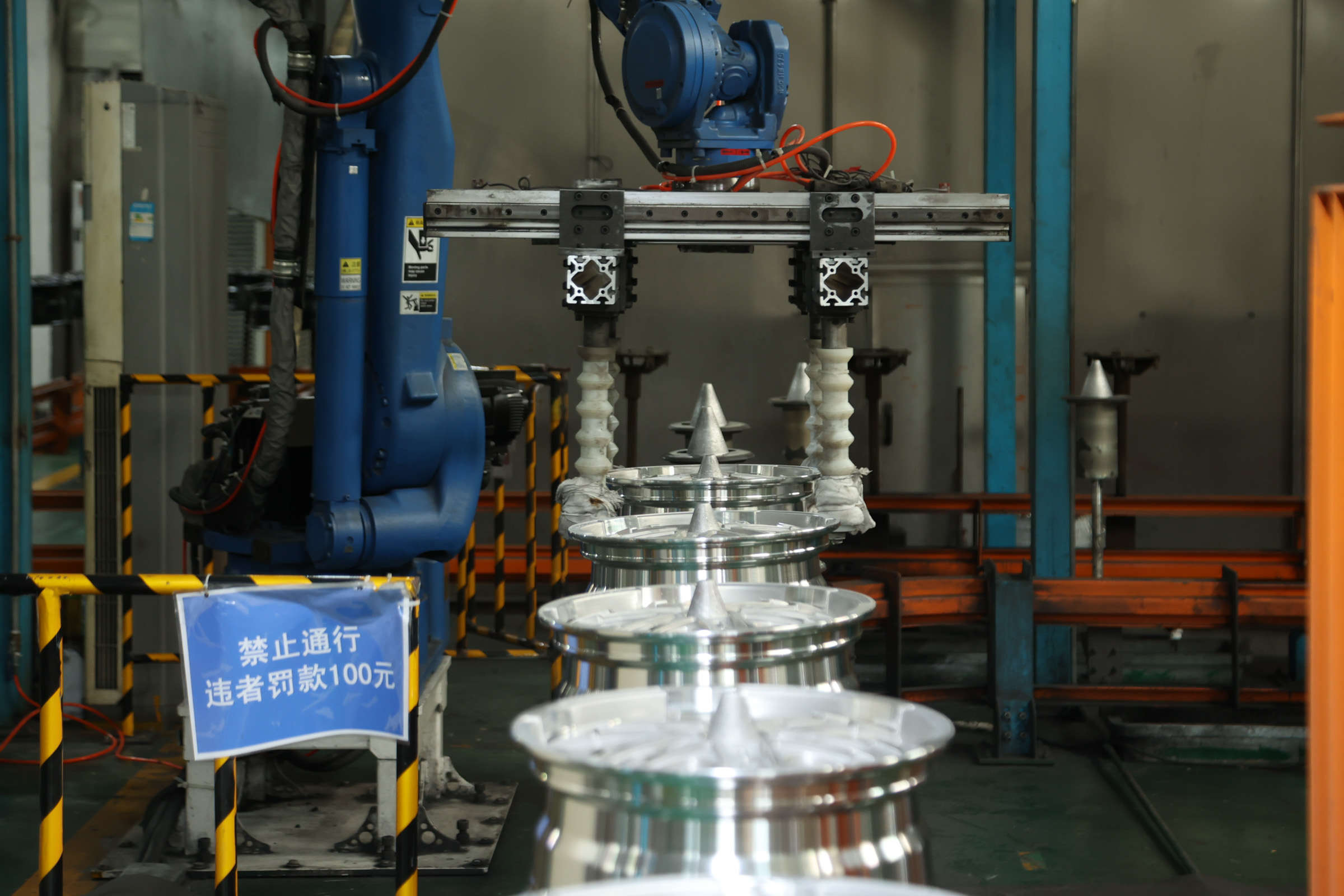

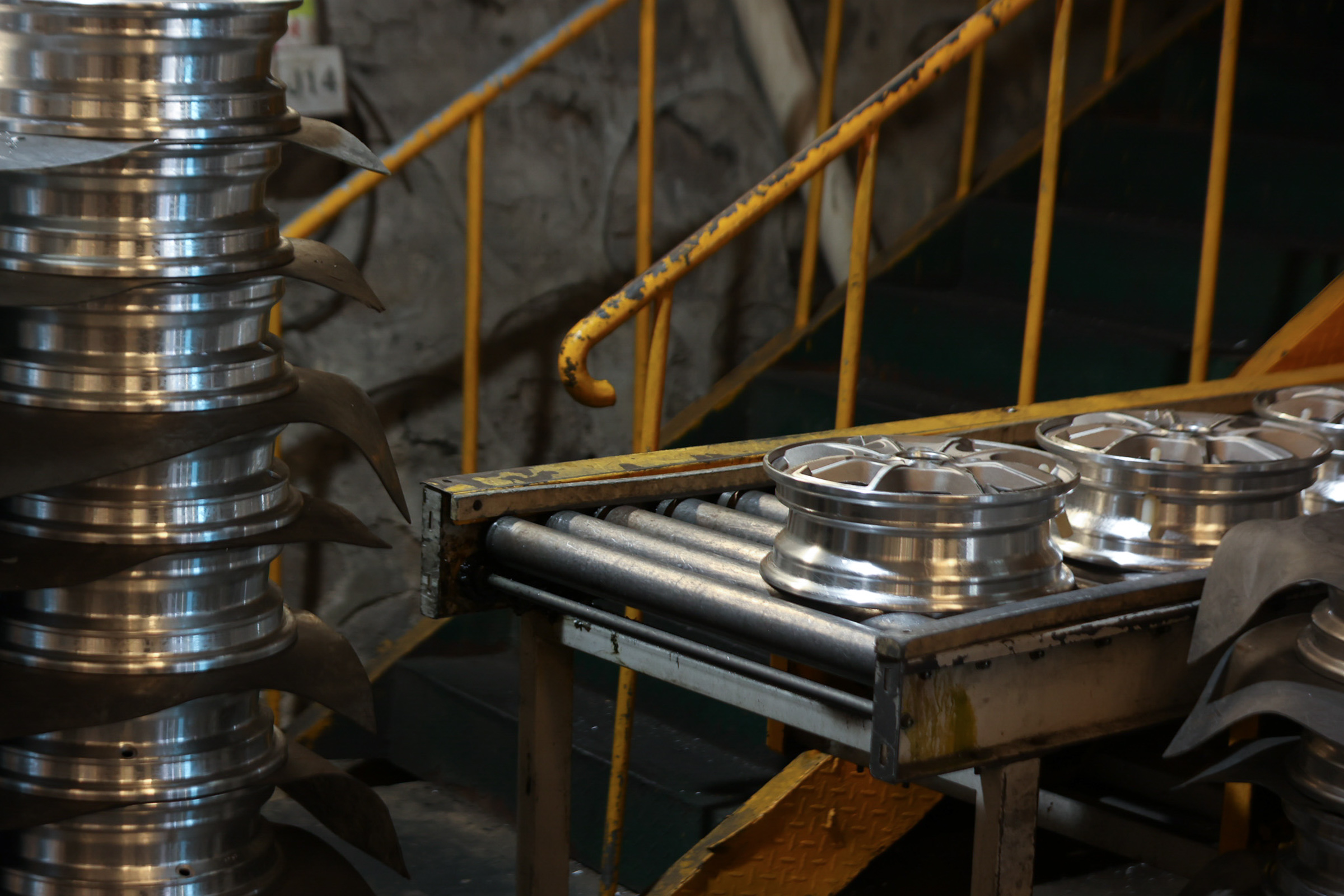

Production process

Low-pressure casting wheels

Custom Products

Suitable for a variety of models, PCD108-120*5H, thin spokes are sharper

Material

Made in A356 aluminum alloy

Color

Black Highlight

Surface Process

Vehicle surface design

Design Features

Multi-spoke, V-shaped, more concave stance

66 Available Coupon

Our Advantages

8. The formula has perfect testing equipment, including material testing machine, hardness tester, solid aluminum alloy containing slag quantitative tester, X-ray diffractometer, bending fatigue tester, radial fatigue tester, biaxial fatigue tester, 13° impact tester, 30°/90° impact tester, salt spray test chamber, humidity and heat test chamber, etc., which can carry out the four major testing areas of wheels (dimensional testing, alloy material performance, reliability and safety, coating and We have formed a complete testing system from the incoming inspection of raw materials to the factory inspection of finished products, and our testing capabilities range from material and performance to dimensional and impact and fatigue testing, and then to the testing of the coating performance of finished wheels.

9. Our company has obtained a number of patents by virtue of its strong technical strength: Patent for a clean grinding table based on aluminum alloy wheels.

10. Our company has been focusing on quality, management and environmental protection, and has passed. ISO 9001:2015, IATF 16949, Germany KBA, Japan VIA association ce

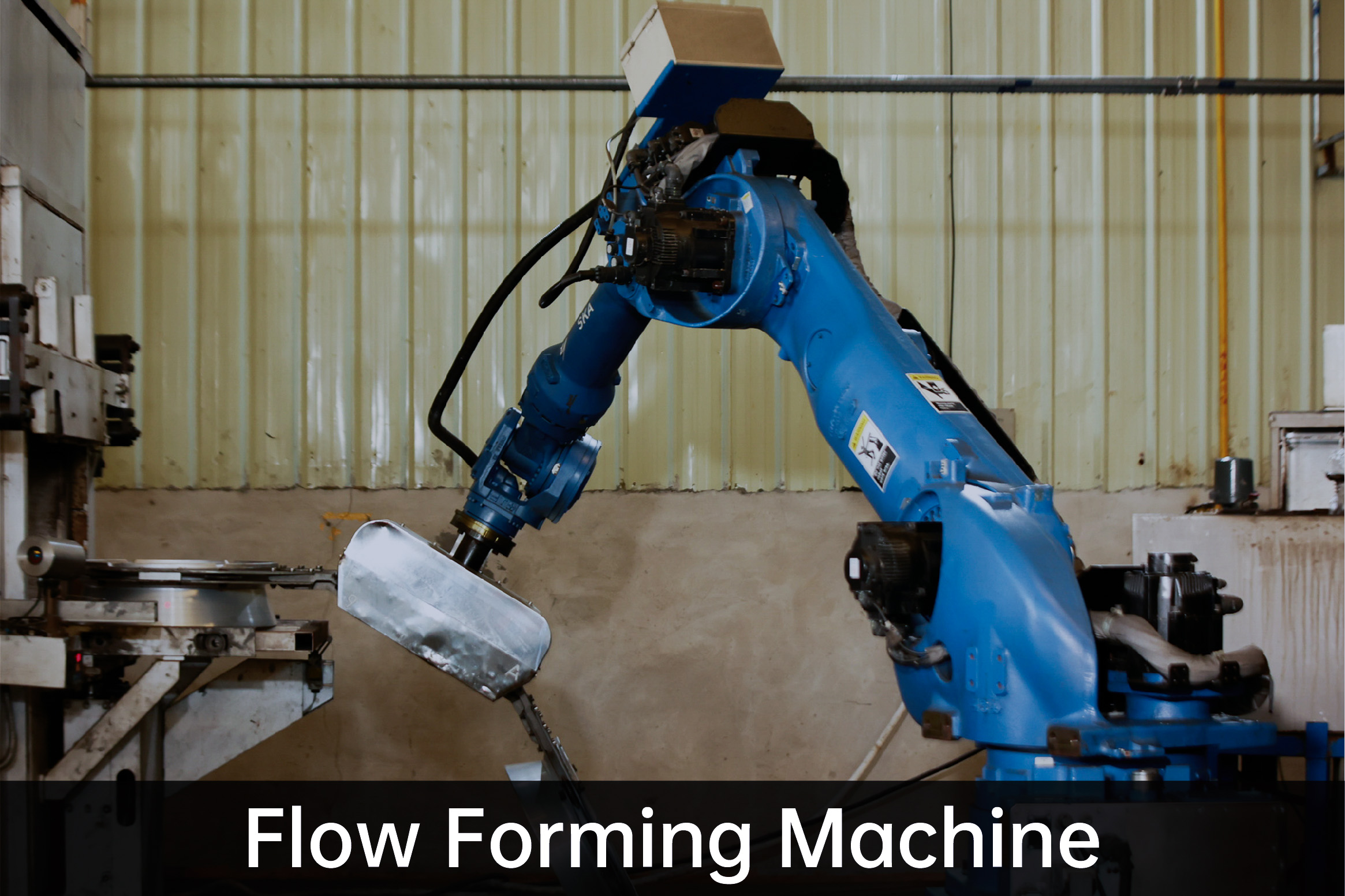

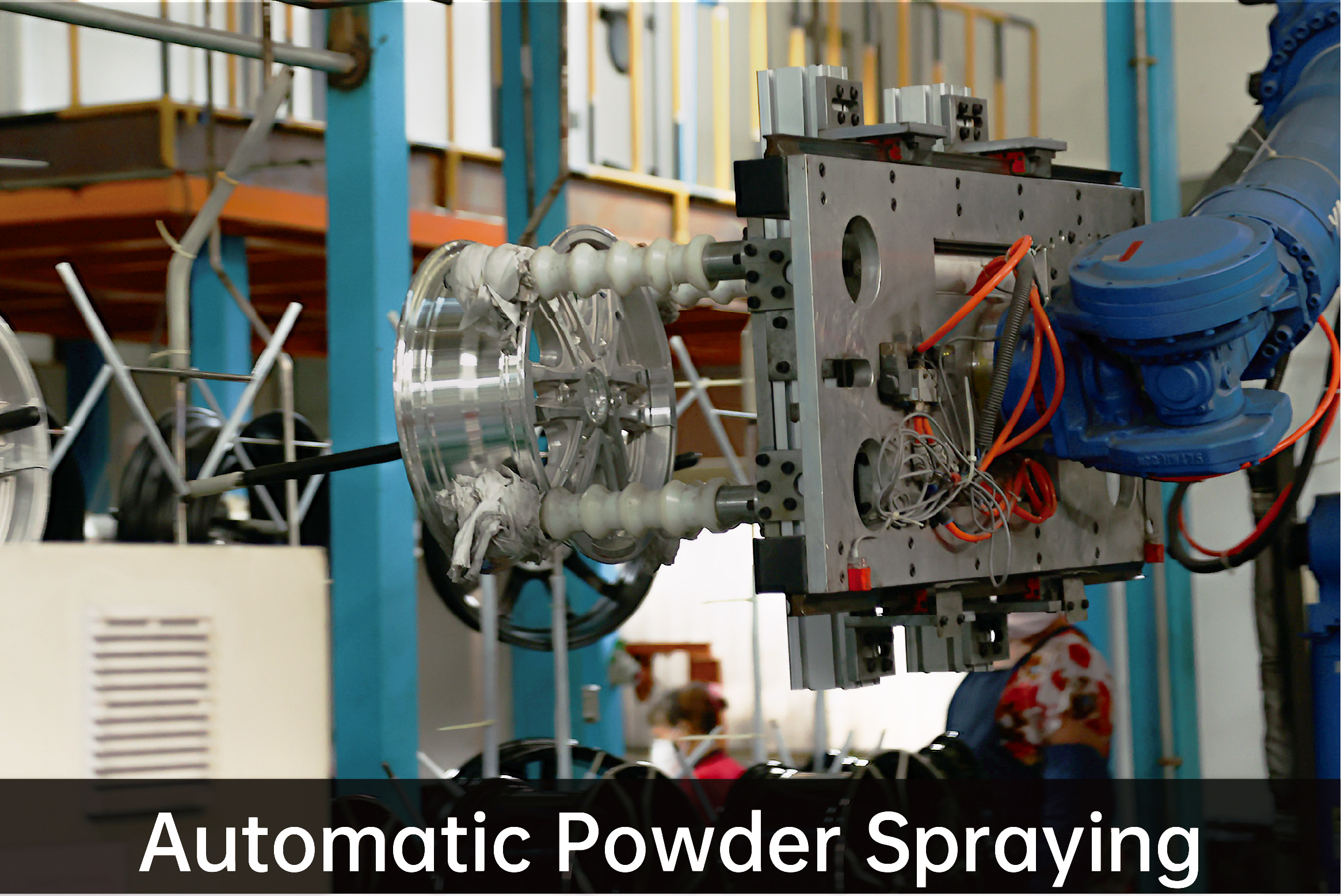

JWHEEL adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers.

Leave A Message