Unleash Elegance: Discover Our Top-Notch 18 Castings! compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.JWHEEL summarizes the defects of past products, and continuously improves them. The specifications of Unleash Elegance: Discover Our Top-Notch 18 Castings! can be customized according to your needs.

Best Quality 18-inch low-pressure casting Facing process Factory.

The company has been engaged in the production and manufacture of ceramic machinery for many years, and has strong mechanical processing capabilities. The produced is far ahead of domestic counterparts in terms of performance, service life, energy saving, noise, etc., and is highly praised by customers in the market. and trust.

Embark on a journey of sheer elegance with our exclusive collection of 18 castings! From intricate designs to timeless classics, our top-notch selection is sure to captivate your senses. Unleash your inner style icon and discover the perfect piece that complements your unique personality. Don't miss out on this opportunity to elevate your style game. Visit us now! ✨🌟 #UnleashElegance #TopNotch18 #JewelryLovers

SEND INQUIRY NOW

Model: J243

MOQ: 300 pieces

Size: 18x8.5

18x9.5

PCD(mm): 100-114.3*5H

Offset(mm): 22/35/48

Center hole CB(mm): 65/73.1

Color Colour: GM33+F5/GM44+F8

Custom Products: All wheels unpainted

| Model | Size | Offset(mm) | PCD(mm) | Center hole CB(mm) | Color | Weight(KG) |

| J243 | 18X8.5 | 35/48 | 100-114.3*5H | 65/73.1 | GM33+F5/GM44+F8 | 10.25 |

| 18X9.5 | 22/35 | 100-114.3*5H | 65/73.1 | GM33+F5/GM44+F8 | 10.84 |

Production process

Low-pressure casting wheels

Custom Products

For PCD 100-114.3*5H , 18 inch models

Material

Made in A356 aluminum alloy

Color

High Gloss Black, Gold

Surface Process

Finish, Brushed

Design Features

Classic multi-spoke, concave, V-shaped design

Polish:

Gross Black

Polish:

Matte Black

Polish:

Flash Silver Gun Metal

Polish:

Tanzannian sapphire blue

Polish:

Gross Bronze

Brush:

Candy Red Clear Coat

Brush:

Brown Clear Coat

Brush:

Blue Clear Coat

Brush:

Bronze Clear Coat

Brush:

Blue Black Clear Coat

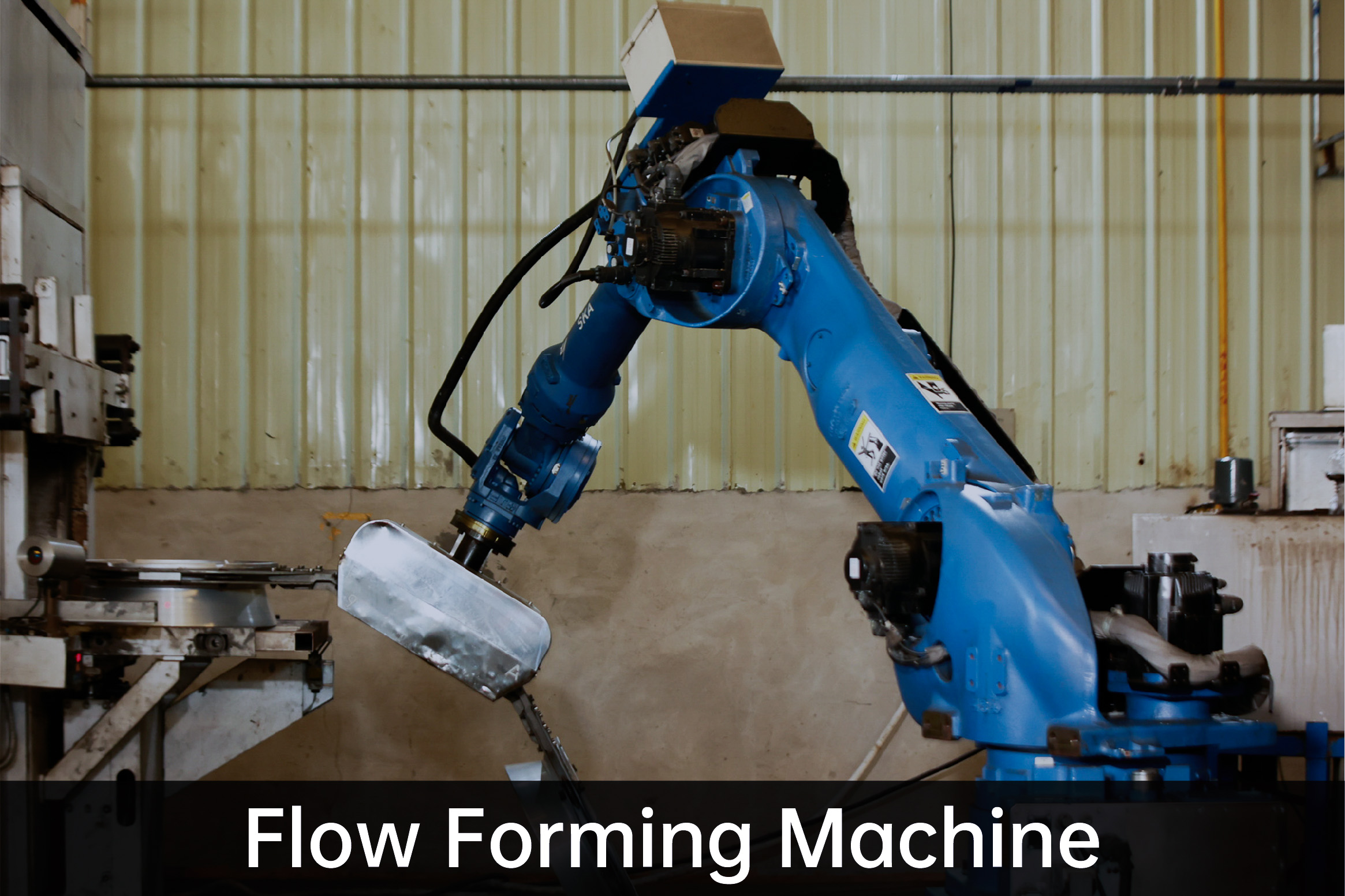

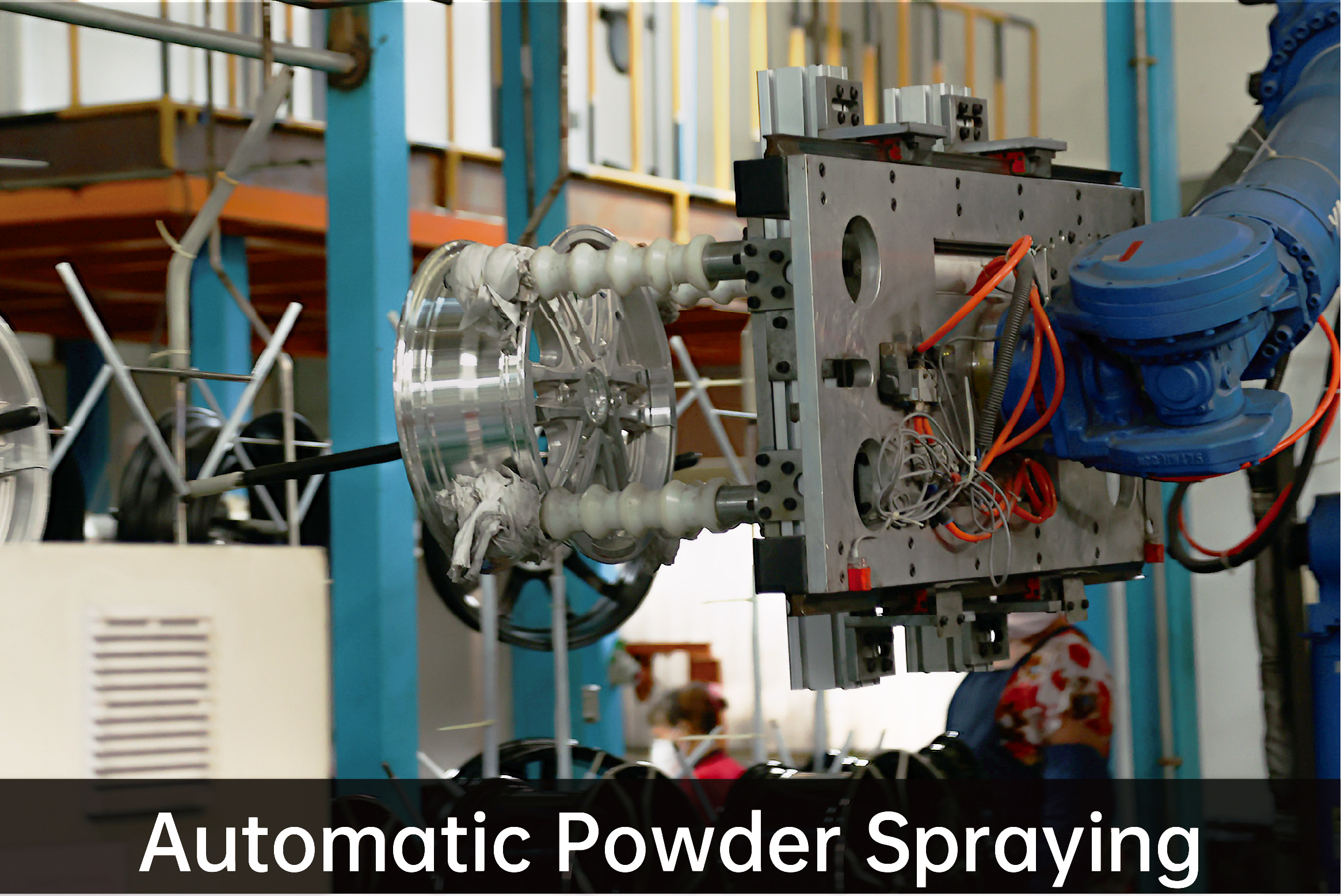

JWHEEL adopts the industry's advanced casting, spinning, machining, painting and inspection equipment, and at the same time, it is equipped with fully automated robot operation platform and testing equipment to fully meet the product requirements of major high-end customers.

Full automatic wheel run out/dynamic balance testing line, suitable for wheel run out and dynamic balance detection.

Run out test: measure the size and phase of the inner and outer radial and axial run out of the wheel.

Dynamic balance test: measure the size and phase of unbalance on both sides.

The lower the flat ratio of the tire, the higher the standard of impact resistance of the wheel. The lower the flat ratio, the greater the impact of the road towards the rim. In response to these changes, JWHEEL uses 30°and 13° impact tests to measure the wheel. (That is, radial impact test is to strike the barrel with a certain hammer weight ).

The 13° impact test mainly uses a heavy hammer to impact the part where the wheel edge connected with the tire at an Angle of 13°, so as to simulate the impact that the car may go through while running on the road, for example rocks or the edge of the road. There are two criteria to measure whether the wheel should be accepted : Spokes should not have penetrating cracks, and the tire should not be completely separated from the barrel within 30 seconds.

Salt spray test is a test that examines the corrosion resistance of the products or metal materials. It uses a salt spray test equipment that creates salt spray environment conditions to detect whether the coating of the wheel is stable, and will there be paint drop, electroplating fade, or cracking, etc.

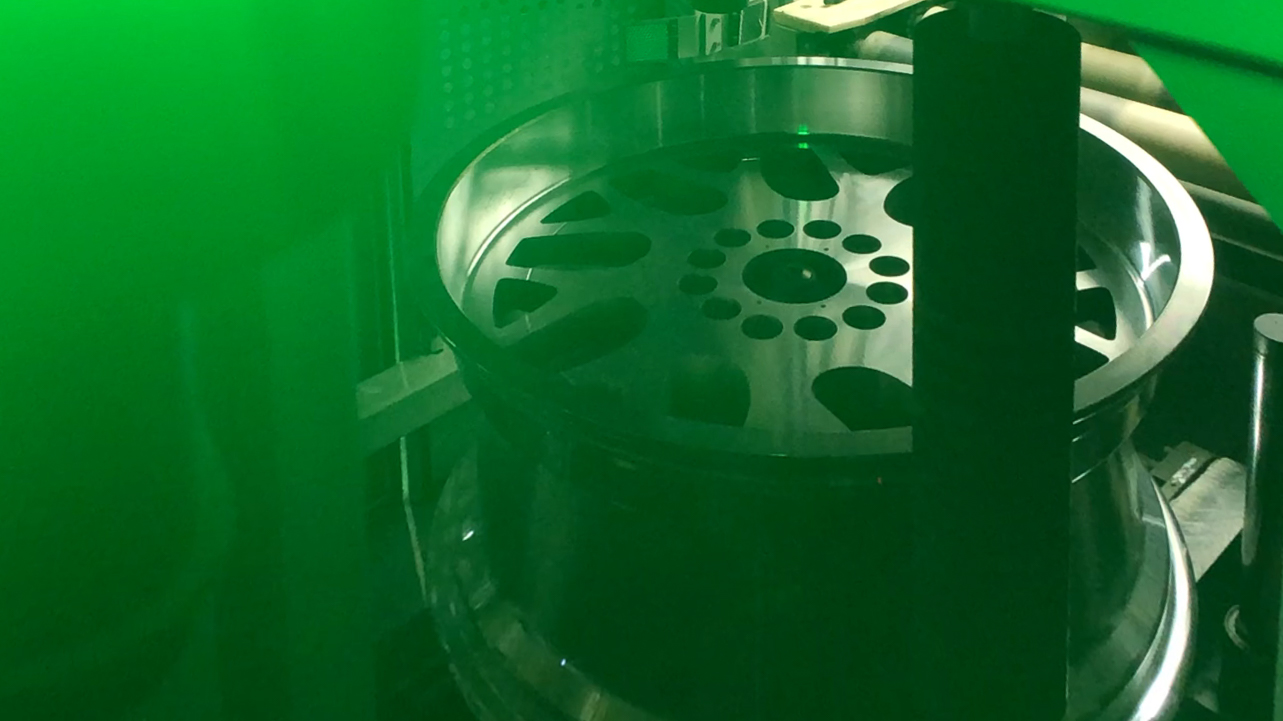

Helium mass spectrometer is used to detect the leakage of the hub. Helium gas is used as the tracer gas. Different masses of gas will be separated according to the mass charge ratio in the mass spectrometry chamber of the mass spectrometer. Then the mass spectrogram of the tracer gas can be obtained, and the hub leakage rate can also be obtained safely, quantitatively and quickly.

Water tightness test - bubble leak detection method. Its detection principle is to close the inner and outer side of the aluminum alloy wheel with sealing disk through external force, and then immerse the wheel and sealing disk in water, as the aluminum alloy wheel is closed, a part of the gas is compressed, resulting in the increase of the pressure of the inner cavity of the wheel. If the wheel rim has a leak hole, the compressed gas will leak out from the leak hole and form bubbles in the water.

No matter what kind of manufacturing method is applied, we can not completely avoid the defects that may be created during the production process. JWHEEL company will find out any unqualified hubs by X-ray detection and then do the recasting. Only 100% good hubs will be moved into the next production process.

The wheel, as a high-speed moving and weight support part of a vehicle, has a vital relation with the safety performance of the whole vehicle and the safety of drivers and passengers. Therefore Jwheel attaches great importance to the hub quality.

There are a series of reasons that may cause casting wheel defects. Such as not strict enough raw material control, unreasonable production process, unreasonable mold structure design, etc. Casting defects includes bubbles, pores, inclusions and looseness, etc. As the internal defects cannot be identified by naked eyes, X-ray becomes a good way to detect the internal quality of the wheel.

Bending test is to determine the solidity of the rim and spoke by simulating the stress on the wheel when the vehicle is shaking. The whole wheel is subjected to a rotational bending force. The load of the wheel in the test varies from 500 kg to 720 kg depending on the wheel parameters, and the number of rotations is not less than 100,000 revolutions according to industry standards. For the appearance of any of the following three phenomena, the test will be determined failed. (1) the wheel can not continue to bear the load (2) New visible cracks appear in any part of the wheel (3) Before reaching the required number of cycles, the offset of the loading point has exceeded 10% of the initial loading.

The radial fatigue test simulates road conditions while driving. Install the hub to the tire to run for 500,000 or even 1,000,000 rotations on the test platform.

Leave A Message