Do alloy wheels last longer than steel? Find out what affects their lifespan, from materials to maintenance, in this in-depth durability guide.

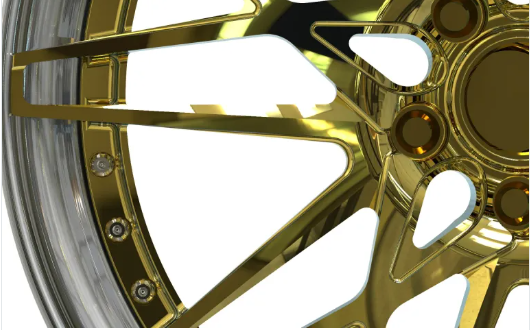

There’s an ongoing debate, whether alloy wheels last longer than standard steel wheels or not? Alloy wheels are often associated with an aesthetic upgrade, which is partially true. However, there’s a lot more to consider. In terms of performance, alloy wheels clearly outperform standard steel wheels. They deliver better overall performance, fuel average, handling, and of course, a more stylish modern look.That said, do custom alloy wheels last longer compared to standard steel wheels? Short answer: Yes, but it depends on many factors. As a matter of fact, not all alloy wheels are made equally. Their longevity largely depends on the material used, manufacturing process, conditions in which they’re used, and, obviously, how well they’re maintained.Let’s take an in-depth look.

As we mentioned above, not all alloy rims are created equal. The quality of aluminum alloy, other metals, and manufacturing methods (such as casting, forging, or flow forming) have a direct impact on longevity.

Further, equally important, is the composition of metals used. The specific ratio of aluminum and other elements used.

Industry leaders, such as JWheels, have been consistently following and implementing the best practices since 1999. Likewise, we continuously innovate to make sure every single product made by us, meets the highest quality standards.

Take an example of a low-pressure casting + spinning method, which results in stronger yet lighter wheels that better resist impact and fatigue.

The conditions or circumstances in which a vehicle has been driven directly impact the lifespan of any type of wheels.

Roads with frequent potholes, speed bumps, and rough surfaces can cause stress, bending, or even cracks over time. Particularly if the wheels are not specifically built for heavy-duty use.

Similarly, exposure to road salt, mud, or moisture in coastal or winter regions can fast-track corrosion if the wheels lack proper protective coatings.

Vehicles used in urban settings, off-road terrains, or commercial fleets often experience more wear.

High-quality alloy wheels with robust structures and corrosion-resistant finishes are better suited for demanding driving environments.

Regular care is required to keep your alloy wheels in good condition.

Dirt, brake dust, and road salt can build up over time and start to eat away at the finish, in the end resulting in corrosion or surface damage.

Cleaning the wheels regularly with a non-abrasive, pH-balanced cleaner helps prevent this.

It’s also important to inspect them from time to time for scratches, cracks, or signs of wear, particularly if the vehicle is used in tough driving conditions.

Maintaining proper tire pressure and alignment reduces unnecessary strain and helps the wheels wear evenly.

Custom alloy wheels could stay sharp and last years, if given a little attention.

Driving habits have a direct impact on a wheel’s lifespan.

Aggressive actions such as sharp cornering, sudden braking, and high-speed driving put extra strain on the wheels. Consequently, increasing the risk of wear or damage over the period of time.

Driving sensibly not only helps extend the life of your wheels but also reduces maintenance costs and contributes to a safer experience for everybody, you and others on the road.

The finish on an alloy wheel works as a protective layer against external elements such as moisture, UV rays, road salt, and debris.

Coating methods, for instance, powder coating and clear coats, help improve corrosion resistance, fading, and surface chipping. Particularly important in regions with harsh weather or extreme temperature changes.

Wheels with high-quality protective finishes tend to maintain their appearance and structural integrity for a longer period. Hence, it makes coating quality a basic premise in long-term durability.

There are various types of chinese alloy wheels, each manufactured using different materials and methods such as casting, forging, or flow forming.

Some are built for high-performance and reduced weight, whereas others focus more on aesthetics. However, not all alloy wheels are designed to handle heavy impact or extreme loads.

When used outside their intended purpose—such as in rugged or off-road conditions—certain alloy wheels may be more prone to cracking under stress.

In contrast, steel wheels are more resistant to bending and cracking under heavy load, making them a better fit for utility vehicles and rough terrain.

Whilst alloy wheels offer superior performance, handling, and fuel efficiency, they can be slightly less durable than steel wheels in harsh environments.

Choosing the right sort of wheel for the intended application is essential for safety and longevity.

Corrosion or rust is a common problem for many, particularly for those living in coastal areas or cold climates where salt is used on roads.

So considering that, chinese alloy wheels are more resistant to rust. On top of it, high-quality alloy wheels often come with advanced finishes like powder coating or clear coats that help shield against moisture, salt, and chemicals.

Regular cleaning and proper care go a long way in preventing corrosion and keeping the wheels in top condition.

Alloy wheels are known for their performance, mainly due to their lighter weight compared to standard wheels. They reduce unsprung mass, allowing the suspension system to respond more efficiently. This results in sharper handling, improved cornering stability, and better braking performance.

The reduced weight also contributes to quicker acceleration and a more responsive driving experience, notably in performance vehicles.

Although steel wheels are tougher in extreme conditions, their added weight can negatively impact agility and fuel efficiency.

High-quality alloy wheels with proper care typically last between 8 to 10 years or even longer.

That said, factors like climate, maintenance, and driving style impact its lifespan.

Knowing when it’s time to repair or replace alloy wheels can prevent safety issues and performance drops.

● Cracks or fractures: These can result from hard impacts or stress over time.

● Corrosion and pitting: Notably common in areas that use road salt.

● Loss of air pressure: Often a sign of a bent or cracked rim.

● Vibration during driving: Indicates imbalance, bent rims, or structural damage.

Minor surface damage can be repaired, however, structural damage perhaps require a replacement. Hence, regular inspection is crucial.

1. Clean Wheels Regularly: Use pH-balanced wheel cleaners to remove brake dust and road grime.

2. Apply Protective Coatings: Wax or ceramic coatings help guard against corrosion and staining.

3. Check Tire Pressure: Underinflated tires increase the risk of rim damage.

4. Avoid Potholes and Curbs: Defensive driving reduces impact damage.

5. Inspect Regularly: Look for scratches, cracks, or corrosion.

6. Store Properly: If you swap wheels seasonally, store them in a dry, climate-controlled space.

7. Choose High-Quality Wheels: Invest in products from reputable alloy wheel companies that prioritize quality, like JWHEEL.

Durability starts at the manufacturing level, depending on what materials are being used, the composition ratio, and the process.

Being in the industry for over two decades, our alloys are made from high-quality material, with just the right composition ratio, advanced techniques, and rigorous testing.

Therefore, our china alloy wheels are built to last.

Our production facilities include fully automated robotic platforms and extensive testing systems.

JWHEEL's testing capabilities include:

● Fatigue testing (biaxial, radial, and bending)

● Impact resistance testing (13°, 30°, and 90°)

● X-ray inspections for internal flaws

● Corrosion, humidity, and heat tests

Each alloy wheel is subjected to rigorous quality control, from raw material inspection to final product testing. Our wheels are built to exceed international safety standards.

JWheel outperforms on all fronts, whether it's performance, quality, or style.

Looking for high-performance, durable Chinese alloy wheels that align with global standards? Contact JWHEEL for a custom quote today.