German customers need to develop newly designed forged wheels, certified by TUV test, comply with safety standards, and the products with fashion design are sold in Germany. The project includes processes of design, production and testing, packaging, etc. JWHEEL team has abundant experience and specializes in providing comprehensive design-assist and testing services from the beginning. Our Engineering team will make a professional calculation base on the design requirements by customer and quality requirements by TUV, to make flexible design solutions to meet our client's expectations.

Project Name: One-piece forged wheel development

Project Location: producing in JWHEEL manufacturer

Project background:

German customers need to develop newly designed forged wheels, certified by TUV test, comply with safety standards, and the products with fashion design are sold in Germany. The project includes processes of design, production and testing, packaging, etc.

Product we supplied: aluminum alloy wheels

Service we supplied: Design testing

Design & Engineering Capability

First of all, we understand that technical input in design development is very important for project developing new design forged wheel in TUV standard. Our JWHEEL team has abundant experience and specializes in providing comprehensive design-assist and testing services from the beginning. Our Engineering team will make a professional calculation base on the design requirements by customer and quality requirements by TUV, to make flexible design solutions to meet our client’s expectations.

For the whole projects, the design, test, production basic information are:

Wheel parameters, wheel load,CAD drawing, Simulated tests, Manufacturing samples, Tests in JWHEEL Lab, Tests by TUV, Manufacturing,Packing,Shipment.

Project Timeline

Day 01, Customer placed order for a set of 19 inch alloy wheel, will send to TUV for testing.

Day 02, Customers provided us with sketches and design requirement. Our engineer made the design files according to the TUV standard.

Day 04, The first design version was completed and passed the system simulation test.

Day 05, Customer discussed the design with us and raised comments on modifying the design.

Day 07, Our engineer revised the design accordingly.

Day 09, Customer review the design and confirm to us.

Day 11, Our engineer confirmed the material info, and made the programming following the design.

Day 13, Material was ready to produce by CNC machine.

Day 16, Produced samples.

Day 18, Sample tested in Jwheel lad according to the TUV standard.

Day 25, Tests were completed and not passed, the design need to revise to reduce the risk to NG.

Day 27, Our engineer revised the design and passed the system simulation test.

Day 28, Producing samples.

Day 30, Sample tested again in Jwheel lad according to the TUV standard.

Day37, Tests were completed and not passed, the design need to revise to reduce the risk to NG again.

Day 38, Our engineer revised the design and passed the system simulation test.

Day 39, Producing samples.

Day 41, Sample tested again in Jwheel lad according to the TUV standard for the third time.

Day 48, Tests were completed and all passed, and samples were in good status.

Day 50, Producing and inspecting wheels for the order of customer.

Day 52, Wheels are packaged and shipped to TUV for testing.

Day 66, TUV announce tests were passed, a certificate would be issued to customer.

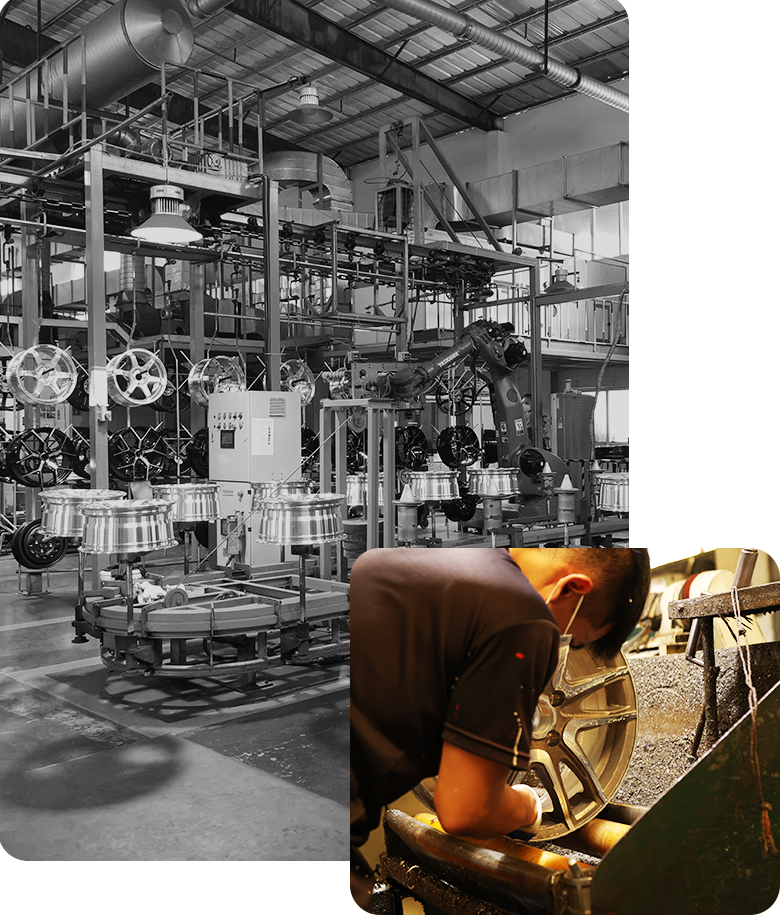

Qualified materials and good manufacturing are very important for a good project, our processes have been certified by ISO 9001 standards. JWHEEL configure fully automatic robot operation platform and online monitoring and testing equipment. Our manufacturing process goes through rigorous quality control inspection both by human and computerized testing. Alloy wheel is the safety part in the vehicle, as well safety are the most important for all our projects, as the professional manufacturer of wheels are required to pass the three performance tests:

(1) Impact test

(2) Bending fatigue test

(3) Radial fatigue test

TUV is a German quality standard certification body.

In the TUV test, it is required that in the bending fatigue endurance test and the radial fatigue endurance test, the hub shall not crack at 1 million revolutions, and the screw torque shall not be reduced by more than 30%; in the impact test, cracks shall not occur and shall not appear within one minute. Tire pressure decreased. It can be seen that Germany's TUV test standards are the most stringent.

Jwheel, as an professional wheel manufacturer, concentrates in R&D and manufacturing of aluminum alloy wheels, including casting wheels, forging wheels and flow-form wheels. The products of it have passed the certifications of SEI、SEMA,VIA, JWL, JWL-T, TUV and so on. Since establishment, Jwheel has been developing steadily, with rich experience of designing and producing aluminum alloy wheels. It has earned the appreciation of both domestic market and foreign market with its high technology, good quality and customer service. It provided OEM service to many international brands like Vossen, OE Wheel, TSW, Rays, ProLine, Oxygen, AUTEC, etc., and it also provide ODM service, that is, for producing a new wheel, you can just provide a sketch, drawing or picture, and then Jwheel will finish the rest parts. By the way, the MOQ of forging wheels is four. (For more information, just go to the website: https://www.jjjwheel.com)